- March 12, 2025

- Posted by: feinuojixie

- Category: Injection Molding News

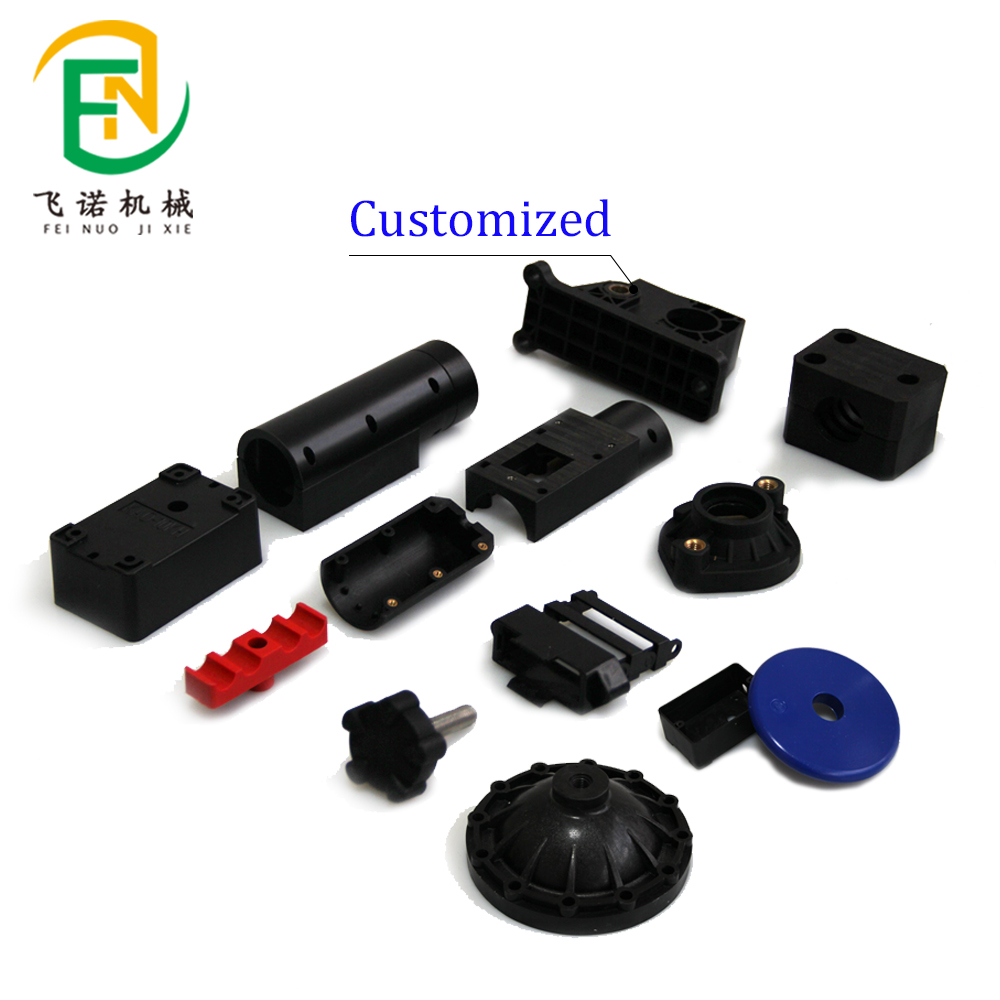

ABS injection moulding is transforming modern manufacturing by offering a cost-effective and highly efficient solution for producing durable plastic components. Acrylonitrile Butadiene Styrene (ABS) is a versatile thermoplastic known for its strength, impact resistance, and excellent surface finish, making it a preferred choice for various industries.

From automotive parts to consumer electronics, ABS injection moulding enables manufacturers to produce complex, high-quality designs with remarkable precision. This process not only enhances production speed but also minimizes material waste, making it an economically and environmentally viable option. As technology continues to evolve, ABS injection moulding is playing a crucial role in shaping the future of industrial production.

Understanding ABS Injection Moulding

ABS injection moulding is a specialized manufacturing process that involves injecting molten ABS plastic into a mould to create precise and durable components. ABS plastic, or Acrylonitrile Butadiene Styrene, is a thermoplastic polymer known for its high impact resistance, strength, and excellent surface quality. These properties make it an ideal choice for a wide range of applications.

The process of ABS injection moulding starts with heating ABS resin pellets until they become molten. This molten plastic is then injected into a pre-designed mould cavity under high pressure. Once cooled and solidified, the finished product is ejected, and any necessary finishing touches, such as trimming or polishing, are applied. This efficient method allows manufacturers to produce complex and high-quality plastic components with minimal material waste.

The Advantages of ABS Injection Moulding

One of the key reasons for the widespread adoption of ABS injection moulding is its numerous advantages over other manufacturing methods.

-

High Durability and Impact Resistance

ABS plastic is known for its toughness and ability to withstand heavy impacts, making it ideal for applications where durability is essential. -

Excellent Surface Finish

Products made with ABS injection moulding often have smooth, glossy, or matte finishes, which enhance their aesthetic appeal and functionality. -

Cost-Effective Mass Production

The injection moulding process allows for the rapid production of large volumes of identical parts, reducing overall manufacturing costs. -

Design Flexibility

ABS injection moulding enables the creation of complex and intricate shapes, making it suitable for detailed and precision-engineered components.

Key Industries Benefiting from ABS Injection Moulding

ABS injection moulding plays a vital role in several industries, providing manufacturers with reliable and cost-efficient solutions for high-quality plastic parts.

-

Automotive Industry

ABS is widely used in vehicle interiors and exterior parts due to its strength and heat resistance. Components such as dashboards, trim panels, and bumpers benefit from the durability of ABS injection moulding. -

Consumer Electronics

Many electronic devices, such as laptops, remote controls, and smartphone casings, utilize ABS plastic for its aesthetic finish, impact resistance, and lightweight properties. -

Medical Equipment

ABS injection moulding is essential in the medical field for producing durable and hygienic components like device casings, handles, and protective covers. -

Toys and Household Products

ABS plastic is commonly used in manufacturing high-quality toys, kitchen appliances, and furniture components due to its safety, durability, and smooth surface finish.

The ABS Injection Moulding Process: Step by Step

-

Material Preparation

High-quality ABS pellets are selected and dried to remove moisture, ensuring consistent melting and injection. -

Melting and Injection

The ABS pellets are heated until they reach a molten state and then injected into the mould under high pressure to fill the cavity completely. -

Cooling and Solidification

Once inside the mould, the plastic begins to cool and solidify, forming the desired shape with precise dimensions. -

Ejection and Finishing

The solidified product is ejected from the mould, and any excess material or imperfections are trimmed, polished, or coated for a refined finish.

Innovations in ABS Injection Moulding

The manufacturing industry continues to innovate, enhancing the efficiency and sustainability of ABS injection moulding.

-

Automation and Robotics

Advanced robotics streamline the moulding process, increasing precision, speed, and efficiency. -

Sustainable Practices

Recycling ABS materials and reducing production waste contribute to environmentally friendly manufacturing. -

Smart Moulding Techniques

Innovations such as AI-driven moulding optimize production parameters, ensuring minimal defects and improved material usage.

Challenges and Solutions in ABS Injection Moulding

Despite its advantages, ABS injection moulding presents certain challenges. However, manufacturers are constantly developing solutions to overcome these issues.

-

Common Defects Such as Warping and Sink Marks

Uneven cooling can lead to warping, while improper injection pressure may cause sink marks. Advanced cooling systems and optimized mould designs help mitigate these issues. -

Optimizing Mould Design for Better Results

Proper mould design, including venting and gate positioning, ensures consistent part quality and reduces defects. -

Overcoming Production Limitations

By integrating cutting-edge monitoring systems, manufacturers can improve efficiency and reduce production errors.

Future Trends in ABS Injection Moulding

The future of ABS injection moulding is shaped by technological advancements and environmental considerations.

-

Eco-Friendly Alternatives

The development of biodegradable and recyclable ABS materials aims to reduce environmental impact. -

Digital Manufacturing and AI-Driven Processes

Artificial intelligence and digital simulations are enhancing quality control and production efficiency. -

Expanding Applications in Aerospace and Renewable Energy

ABS injection moulding is finding new applications in high-performance industries that require durable and lightweight materials.

Conclusion

ABS injection moulding has revolutionized the manufacturing industry by providing an efficient, cost-effective, and highly versatile method for producing durable plastic components. With applications in automotive, electronics, medical, and consumer goods, this process continues to drive innovation across multiple sectors.

As technology advances, the adoption of sustainable practices and smart manufacturing techniques will further enhance the efficiency and eco-friendliness of ABS injection moulding. By embracing these developments, manufacturers can continue to deliver high-quality products while reducing environmental impact and optimizing production costs.