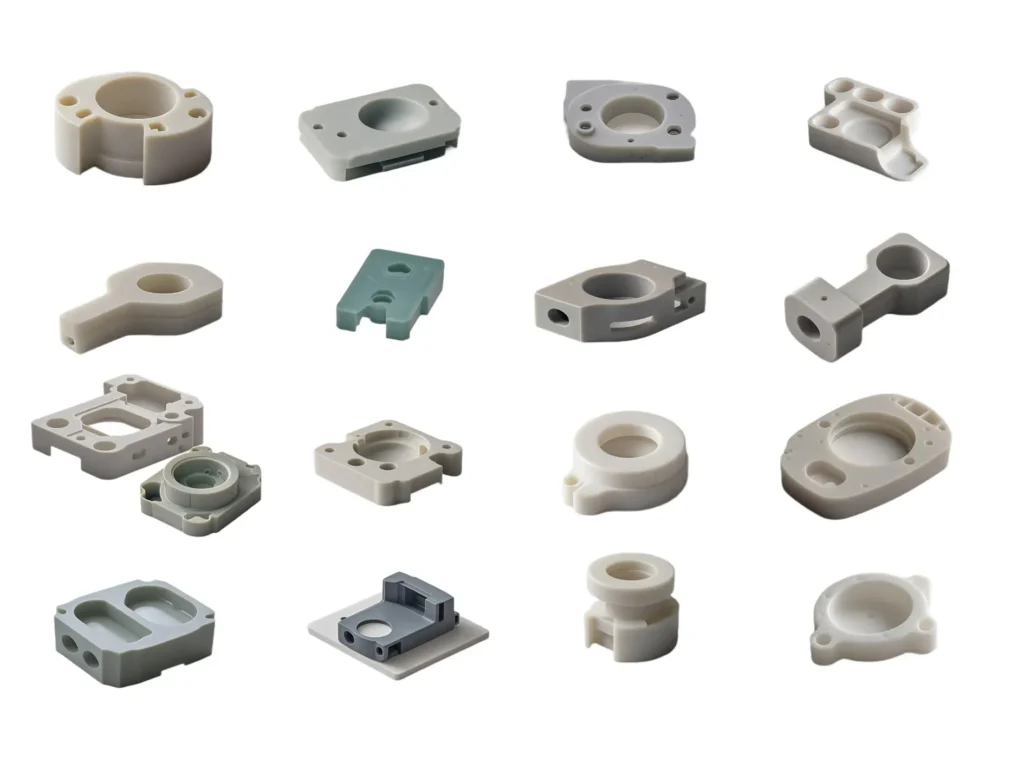

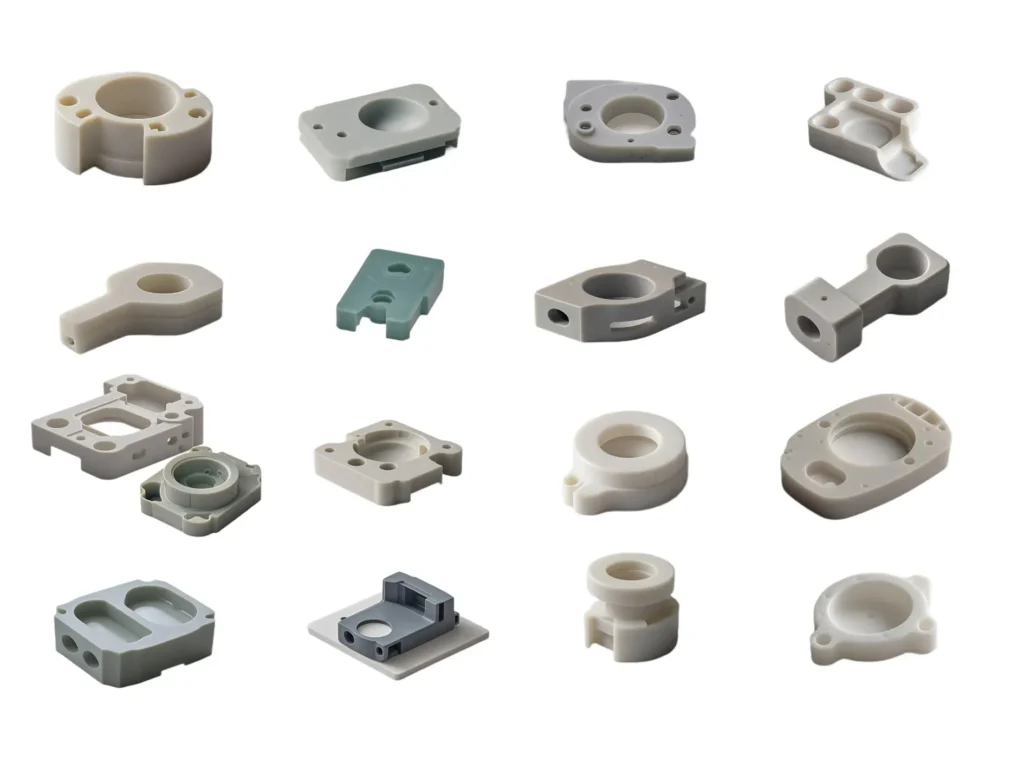

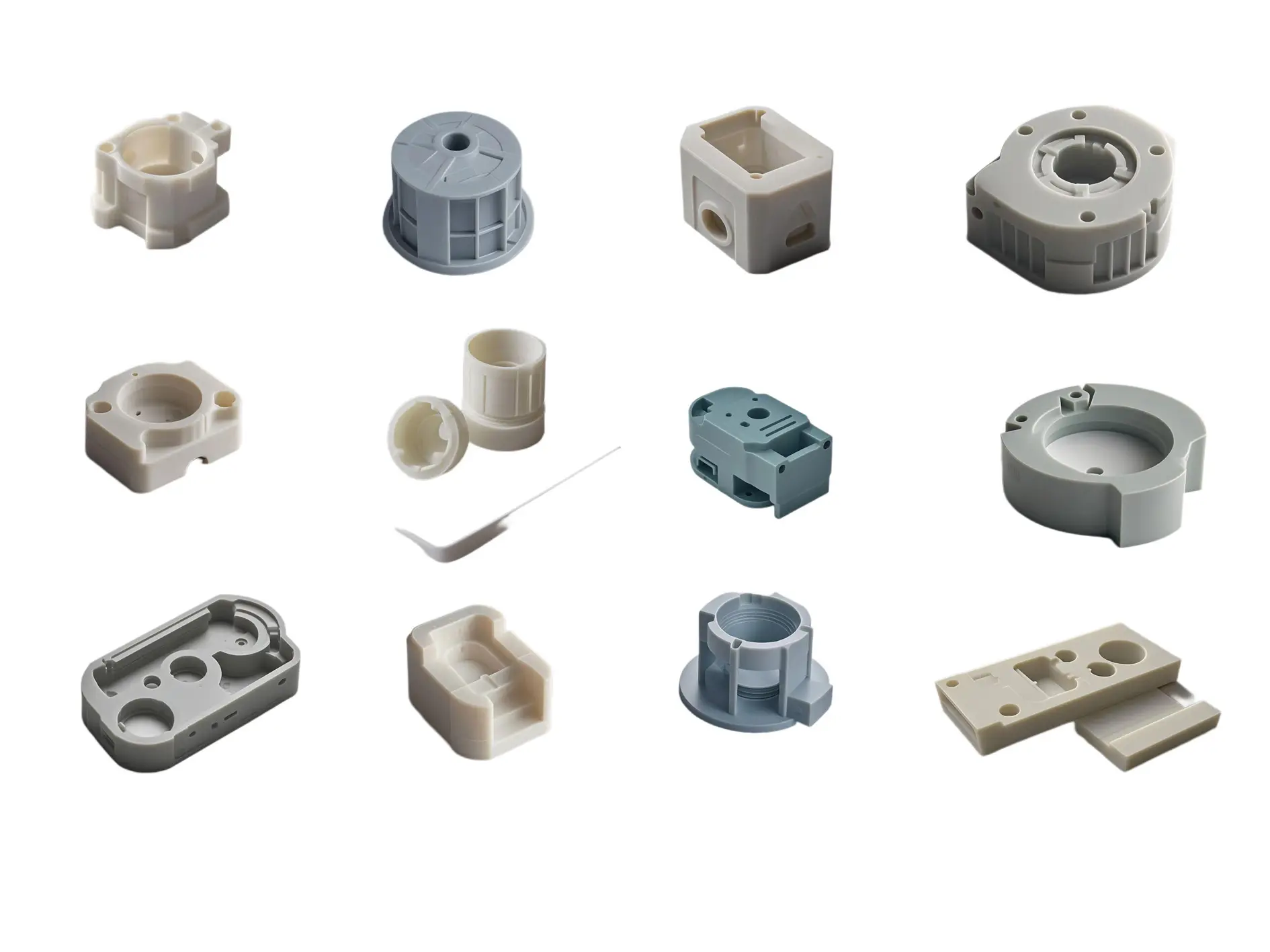

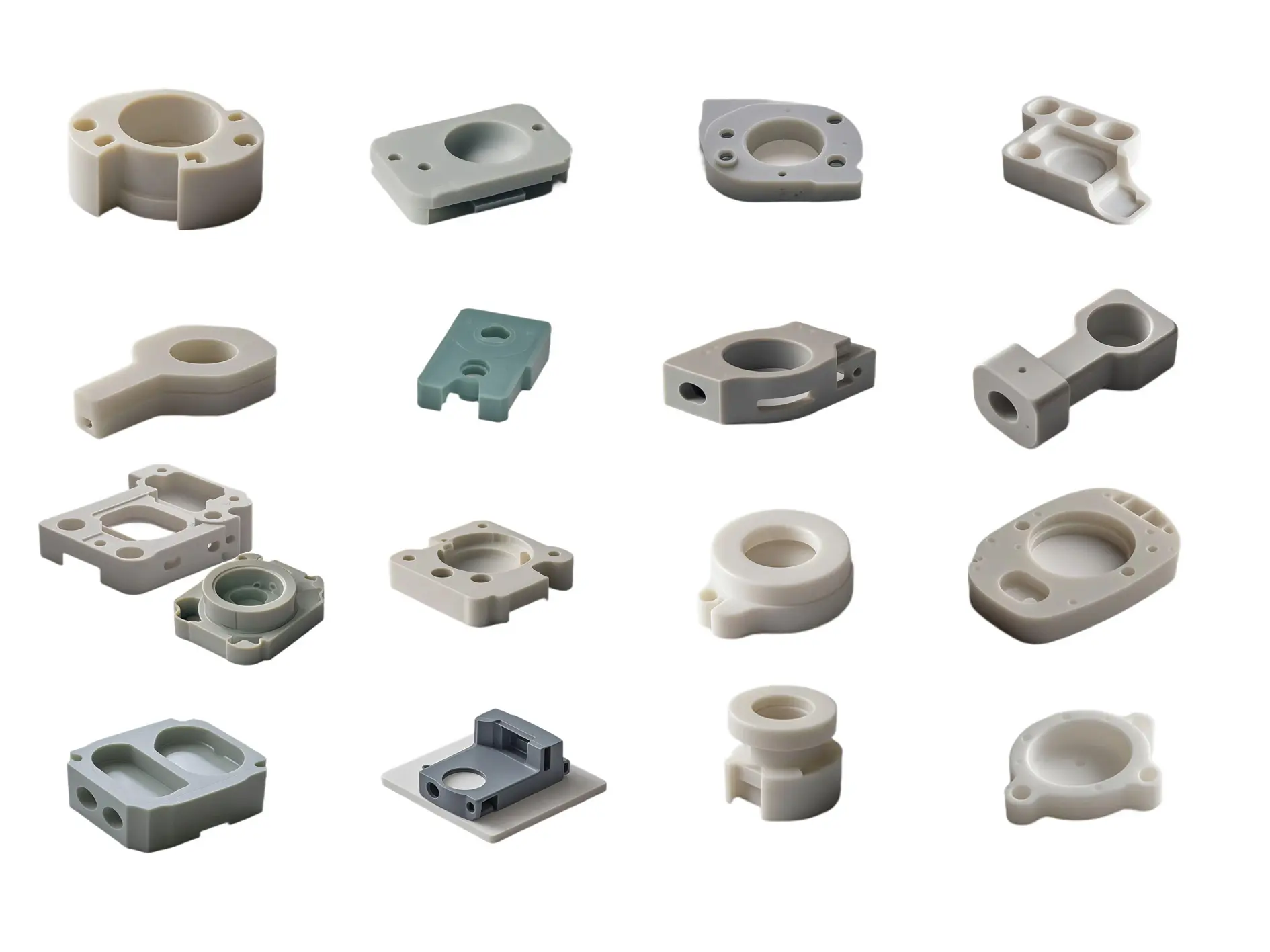

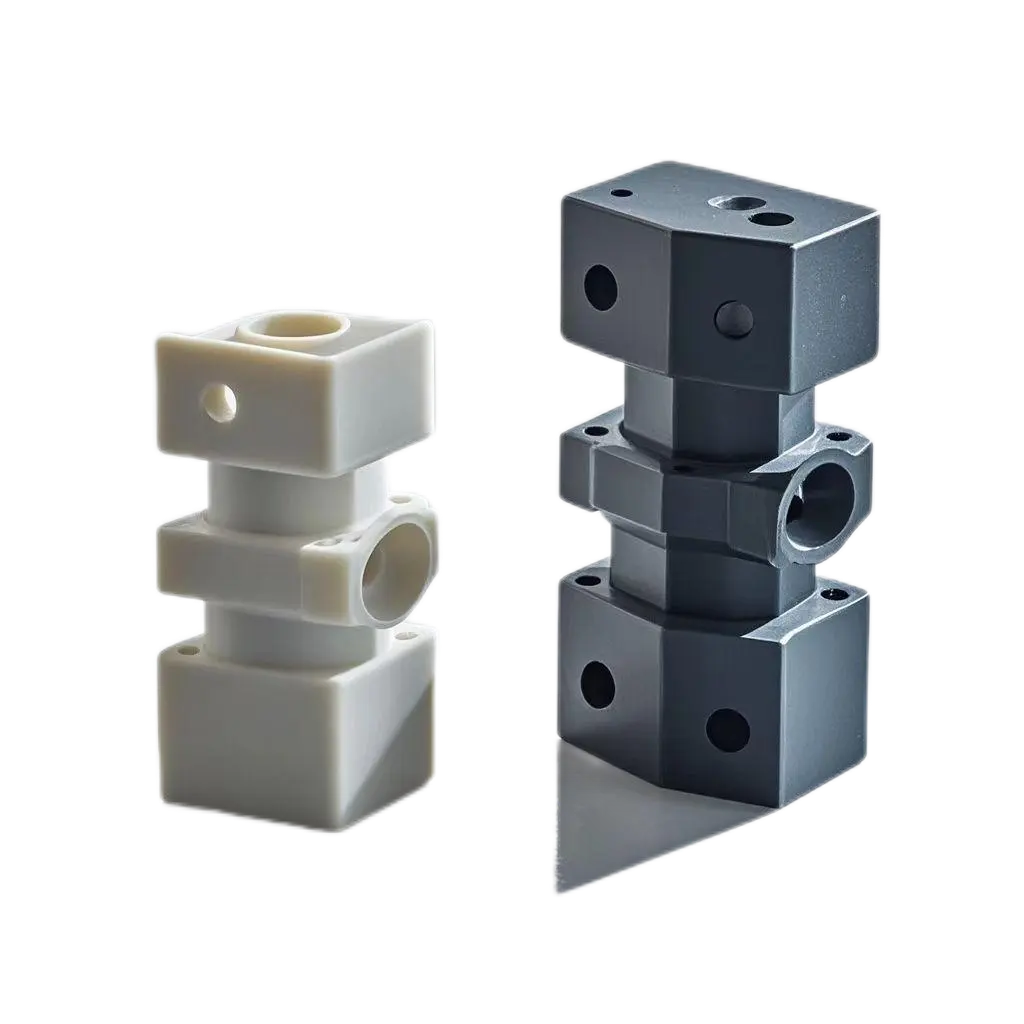

Take your production to the next level with our customized molding service for PP & ABS plastic, specifically designed for injection machine parts that demand durability, dimensional accuracy, and long-term performance. We specialize in high-quality plastic injection molding solutions that meet the rigorous demands of modern manufacturing.

Plastic Injection Molding Parts Parameters

| Materials | Aluminum、stainless steel、 titanium alloy、brass、 etc. |

| Dimensions | Customization |

| Surface treatment | Powder coating, electroplating, oxide, anodizing |

| Process | Turning, milling, polishing, laser cutting, bending, welding, stamping, wire cutting, etc. |

| OEM/ODM | Accept |

| Drawing Format | 3D/CAD/Dwg/IGS/STP |

| Color | Customization |

| Application | Medical equipment, automotive, construction, capital equipment, instrumentation, telecommunications, energy, electrical appliances, etc. |

Key Advantages of Our Customized Injection Machine Parts

-

Tailor-Made Precision

Each component is custom-designed to perfectly fit your injection machinery, ensuring flawless integration and performance. No compromise on dimensions, alignment, or surface finish. -

Reliable Material Performance

PP and ABS plastics offer an ideal combination of strength, flexibility, and durability. Whether the part faces mechanical stress, temperature variations, or long-term wear—our materials deliver. -

Consistent Quality in Every Batch

With fully automated production lines and real-time monitoring systems, we ensure consistency from the first part to the last. -

Cost-Efficient Production at Scale

Our factory setup allows for high-volume production without sacrificing quality. We offer competitive pricing with zero hidden costs—perfect for long-term partnerships. -

Comprehensive Testing & Certification

All parts can be delivered with dimensional inspection reports, RoHS/REACH compliance certificates, and other documentation upon request.

Flexible Customization Services

We understand that each project is unique. That’s why we offer:

-

Material selection (besides PP & ABS, we also support PC, PA, PBT, and more)

-

Color customization (Pantone-matched or textured finishes)

-

Part marking or branding (laser engraving, pad printing, or embossing)

-

Multi-cavity mold production for high-efficiency runs

-

Mold maintenance & storage for repeat orders

From concept to finished part—we support you at every step.

Customer Support & Communication

Your satisfaction is our top priority. When you work with us, you get:

-

One-on-one engineering support for DFM (Design for Manufacturing) optimization

-

Clear project timelines with regular production updates

-

Free samples for bulk orders (conditions apply)

-

After-sales support for any molding or fitting concerns

We respond within 24 hours and speak fluent English for smooth communication with global buyers.

Our Cooperation Process

-

Send Your Inquiry

Share your 2D/3D drawings, samples, or ideas. We sign NDAs for confidentiality. -

DFM & Quotation

Our engineers analyze your design for mold feasibility and cost optimization. -

Tooling & Sample Production

Once approved, we begin mold making and provide samples for validation. -

Mass Production & QC

After sample approval, we enter bulk production with full QC inspection. -

Packaging & Shipping

Secure packaging + reliable freight forwarding = fast and safe delivery to your door.

Industries We Serve

-

Plastic parts for injection molding machinery and accessories

-

Components for automotive assembly lines

-

Enclosures for industrial automation and electronics

-

Medical-grade parts for lab and diagnostic devices

-

Housings and fixtures for home appliances and tools

🔧 Let’s Build Your Custom Plastic Parts Together!

Whether you’re sourcing replacement injection machine parts or launching a brand-new product, we’re here to support your goals with expertise and precision.

📩 Contact us now to get your free quote and let’s discuss how we can support your project.

There are no reviews yet.