- May 13, 2025

- Posted by: feinuojixie

- Category: Injection Molding News

Most drivers take tire safety for granted—until something goes wrong. One of the most overlooked innovations tucked inside modern tires is the run flat insert, a component that often prevents roadside disasters. This small but powerful piece of technology allows a vehicle to keep moving even after a tire has lost all its air. While not as visible as a spare tire or as flashy as high-performance rims, the run flat insert plays a silent yet critical role in ensuring passenger safety. As the automotive world shifts toward smarter and more compact solutions, understanding what a run flat insert does—and why it matters—is more relevant than ever.

What Is a Run Flat Insert and How Does It Work?

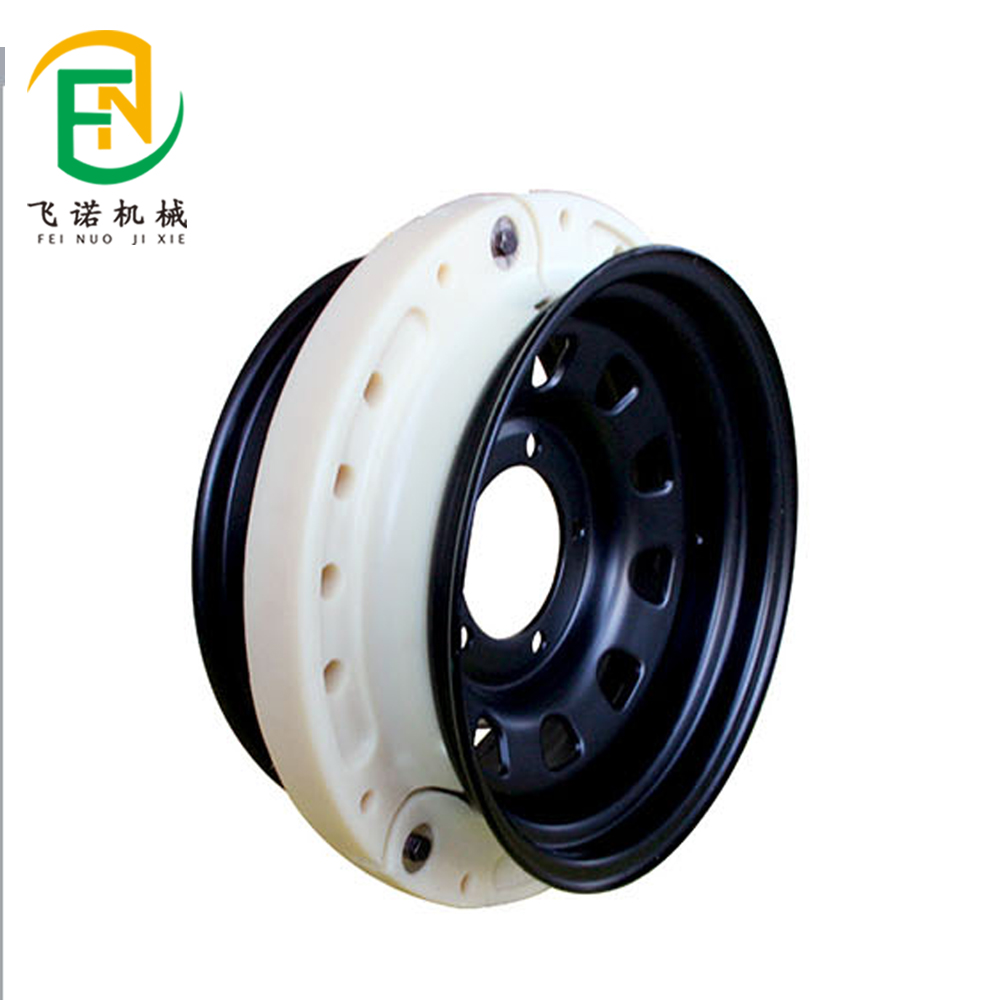

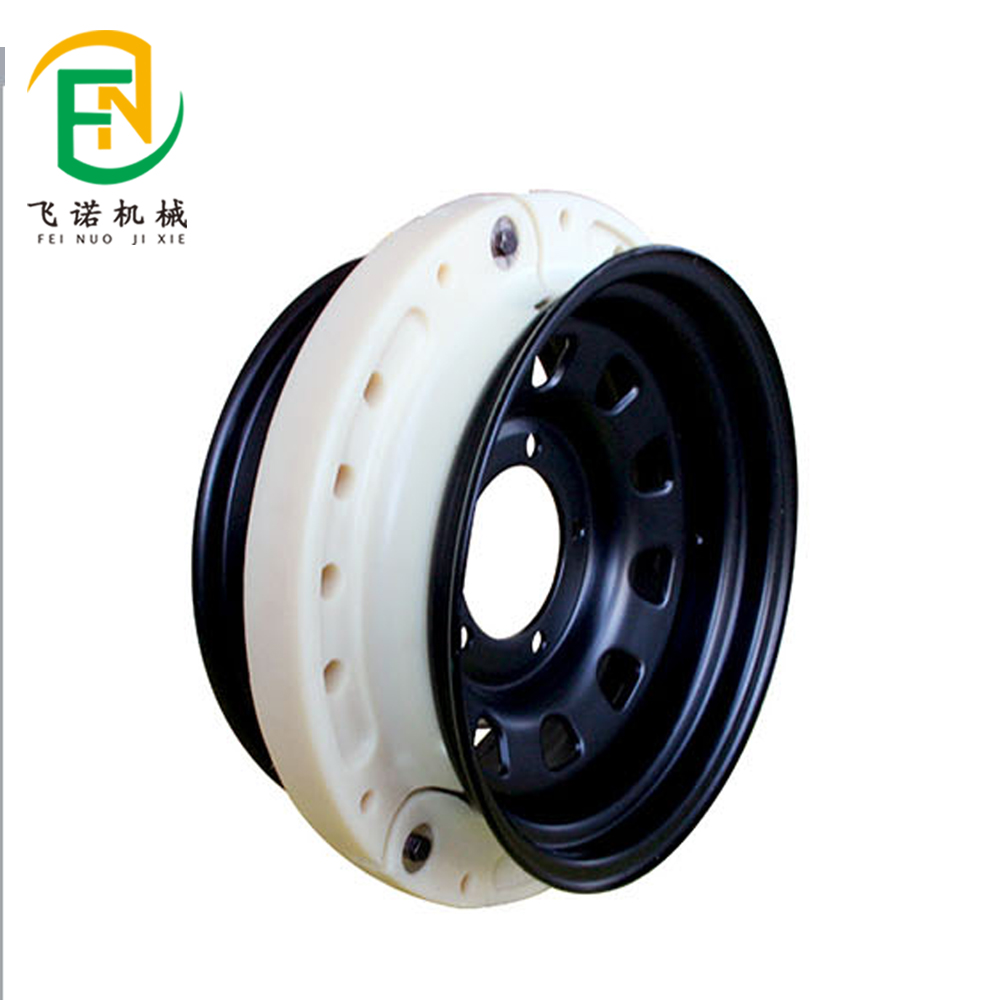

A run flat insert is a specially engineered component, typically made of high-strength rubber or composite material, that sits inside the tire and directly supports the weight of the vehicle when the tire loses air pressure. In the event of a puncture or blowout, the insert prevents the tire from collapsing completely, allowing the driver to maintain control and drive for a limited distance—often up to 50 miles at reduced speeds. This insert absorbs the load, maintains the tire’s shape, and gives the driver enough time to reach a service station without pulling over immediately.

The Evolution of Run Flat Technology

Run flat technology has its roots in military applications where tire failure in combat zones could be fatal. Over the decades, the concept evolved and found its way into high-performance sports cars, armored vehicles, and eventually everyday passenger vehicles. Early run flat systems were heavy and rigid, but advancements in materials and engineering have led to lighter, more adaptable inserts that maintain performance without compromising ride comfort.

Why Automakers Choose Run Flat Insert Over Traditional Spare Tires

Many modern automakers are moving away from including a traditional spare tire in new vehicles. Instead, they are opting for run flat insert systems that free up trunk space, reduce overall vehicle weight, and improve fuel efficiency. From a design perspective, eliminating the need for a spare simplifies vehicle architecture. More importantly, run flat insert systems add a layer of safety by removing the need to change a tire on the roadside—especially valuable in dangerous or isolated areas.

Run Flat Insert vs Run Flat Tire: What’s the Difference?

It’s common to confuse run flat insert with run flat tire, but they are distinct solutions. A run flat tire is designed with reinforced sidewalls that temporarily hold up the car when the tire is deflated. In contrast, a run flat insert is an internal support ring installed within a standard tire, typically on vehicles equipped with specialized wheels. While both technologies serve the same purpose, the insert offers greater reliability in extreme conditions and is often easier to replace or upgrade without needing a full tire redesign.

Key Benefits of Using a Run Flat Insert

The most obvious advantage of a run flat insert is safety. It gives drivers time to respond calmly and find a safe place to repair the issue. There’s no need to stop immediately or risk changing a tire in unsafe environments. Other benefits include improved vehicle stability after a puncture, compatibility with high-load or off-road applications, and reduced reliance on emergency roadside assistance. The insert is also an excellent fit for armored or commercial vehicles that demand consistent mobility.

Limitations You Should Know Before Relying on a Run Flat Insert

Despite its benefits, the run flat insert isn’t perfect. One of the primary limitations is range—you can only drive for a limited distance (typically 30–50 miles) at reduced speeds after a deflation. Inserts can also be expensive compared to conventional tire setups and may require specialized installation. Additionally, not all tires or wheels are compatible with run flat inserts, so retrofitting may not always be possible without changing multiple components.

How Run Flat Insert Enhances Off-Road and Military Applications

In off-road and military environments, reliability can be the difference between mission success and failure. A run flat insert ensures that vehicles can continue operating even after sustaining tire damage from rocks, debris, or hostile conditions. Military vehicles often rely on heavy-duty inserts made of reinforced materials that can endure extreme impacts and temperatures. Similarly, off-road SUVs benefit from inserts when traversing rugged landscapes far from help or repair services.

What to Look for When Choosing a Run Flat Insert

Not all run flat inserts are created equal. When selecting one, consider factors such as load-bearing capacity, temperature resistance, and compatibility with your vehicle’s wheel and tire size. Look for inserts made from durable, high-performance materials like polyurethane or reinforced rubber. It’s also wise to choose products from reputable manufacturers with industry certifications. Installation and maintenance support should also be a consideration, especially for commercial fleets.

The Future of Run Flat Insert in Modern Mobility

As electric vehicles (EVs), autonomous cars, and lightweight designs reshape the automotive industry, the role of run flat insert is set to expand. With EVs, eliminating the spare tire saves battery space and weight—making run flat insert systems even more attractive. Moreover, smart tire technologies may soon integrate with inserts to monitor tire health in real-time and alert drivers before a failure occurs. We can also expect improvements in materials that extend the usable range and durability of these inserts.

Small Component, Big Impact

The run flat insert may be hidden inside your tire, but its impact on vehicle safety and mobility is impossible to ignore. It transforms a flat tire from a dangerous roadside emergency into a manageable inconvenience. Whether you’re commuting through city traffic or exploring remote terrain, a run flat insert ensures you stay in control when things go wrong. As tire technology continues to evolve, this small component will remain a vital piece of the mobility puzzle—quietly doing its job, keeping you moving forward.