- June 4, 2025

- Posted by: feinuojixie

- Category: Run Flat Guide

In the world of elite performance, every detail matters—whether it’s the traction of a racing tire gripping loose gravel or the responsiveness of a basketball court under an athlete’s feet. As industries evolve, the lines between them begin to blur. Automotive engineers and sports scientists may work in different arenas, but they share a relentless drive for innovation, safety, and speed. One surprising yet powerful example of this crossover lies in run flat all terrain tires—a rugged, resilient technology built for harsh environments—and how their engineering principles are now being translated into the next generation of sports flooring.

Today’s high-performance athletic surfaces are no longer just about cushioning or grip. They’re about dynamic energy return, joint protection, and environmental sustainability. And behind this evolution is a deeper understanding of how materials behave under extreme stress—an area where tire technology excels. Run flat all terrain tires are designed to maintain functionality even when punctured, with engineered inserts and sidewall reinforcements that ensure continued performance. This concept of structural integrity under pressure has found a new home in gyms, courts, and stadiums, giving athletes flooring that supports them as reliably as tires support a vehicle in the toughest conditions.

From the Track to the Court: The Crossroads of Automotive and Athletic Engineering

At first glance, tires and sports flooring might seem worlds apart. But look closer, and the similarities emerge. Both must deliver consistent traction, absorb impact forces, and maintain structural integrity over time. Automotive engineers face similar challenges as sports architects: how to create a surface that is both forgiving and firm, responsive and durable.

Run flat all terrain tires embody this duality. They are built to handle jagged rocks, sharp debris, and unpredictable terrain without losing performance. That same resilience is now informing sports surface innovation. Whether it’s a volleyball court that needs to reduce joint fatigue or a track that must endure thousands of daily impacts, the core question is the same: How do you engineer a surface that performs under pressure?

This shared pursuit of balance—between strength and flexibility, speed and safety—is where these industries converge, setting the stage for new materials and construction techniques.

What Makes Run Flat All Terrain Tires Revolutionary

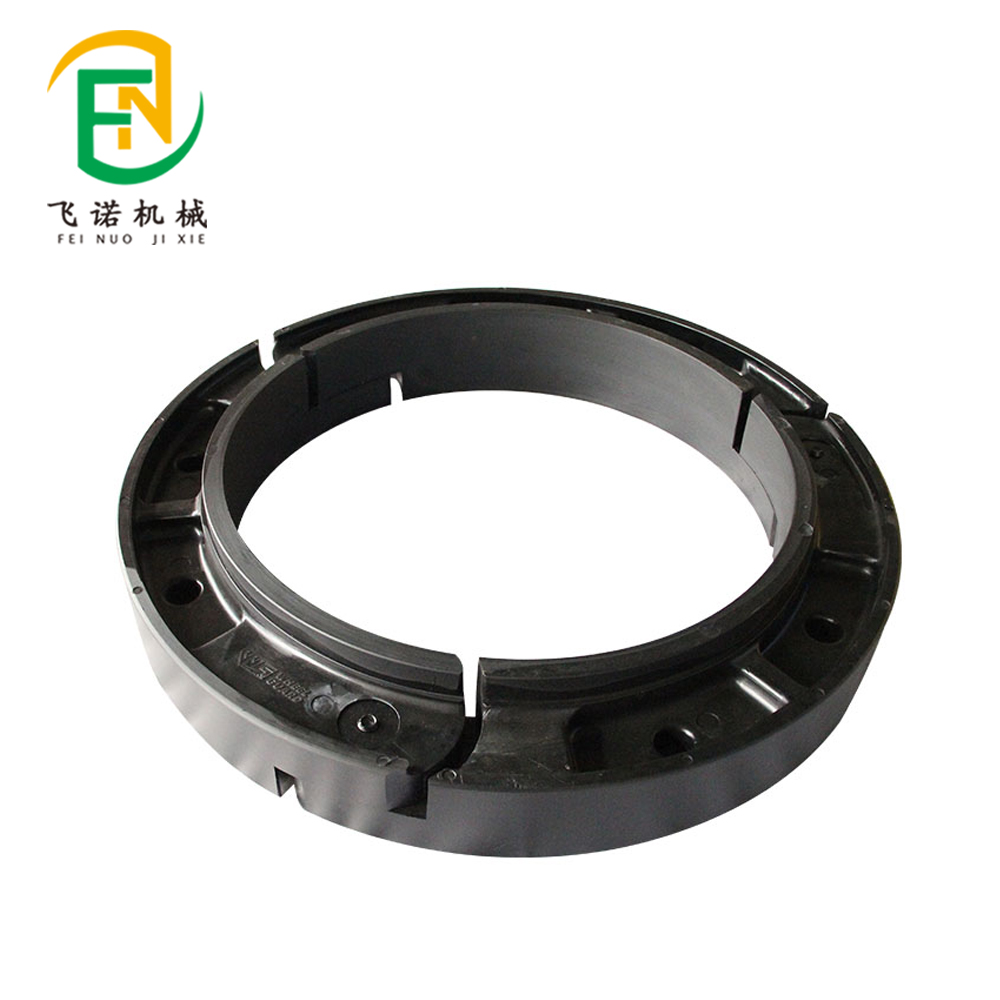

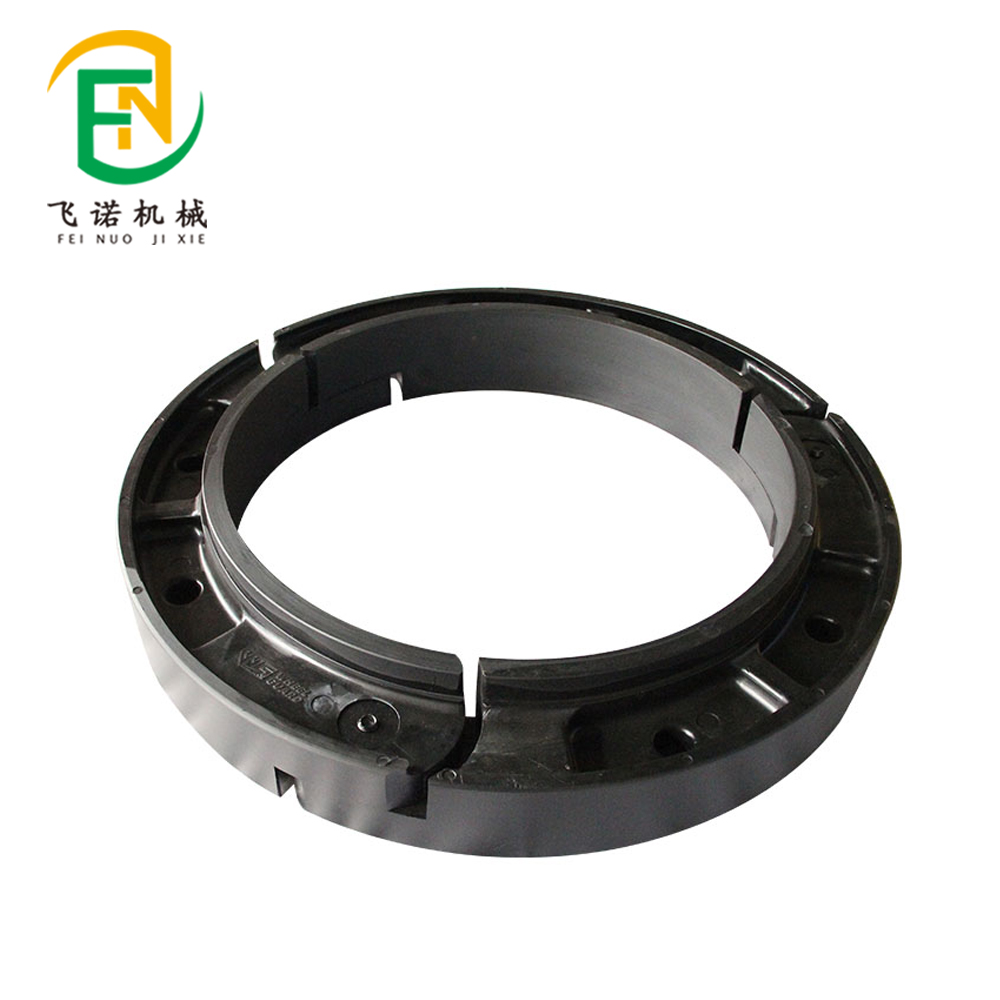

To understand their influence, we must first understand what sets run flat all terrain tires apart. Unlike conventional tires, they are designed to continue functioning even after a puncture. This is made possible through reinforced sidewalls and internal support structures called inserts. These features allow a vehicle to be driven safely for extended distances without air pressure, giving drivers a crucial performance edge.

These design breakthroughs center around three key benefits: shock absorption, structural redundancy, and adaptive support. These same characteristics are essential in elite sports flooring systems. Where a tire must protect both the wheel and vehicle frame, sports flooring must protect an athlete’s joints, tendons, and performance output.

The tire’s ability to “give” under pressure while maintaining a stable ride inspires flooring that can flex and rebound in a similar way. In this sense, the revolution of the road becomes the foundation of the court.

The Birth of Run Flat Inserts for Sports Flooring

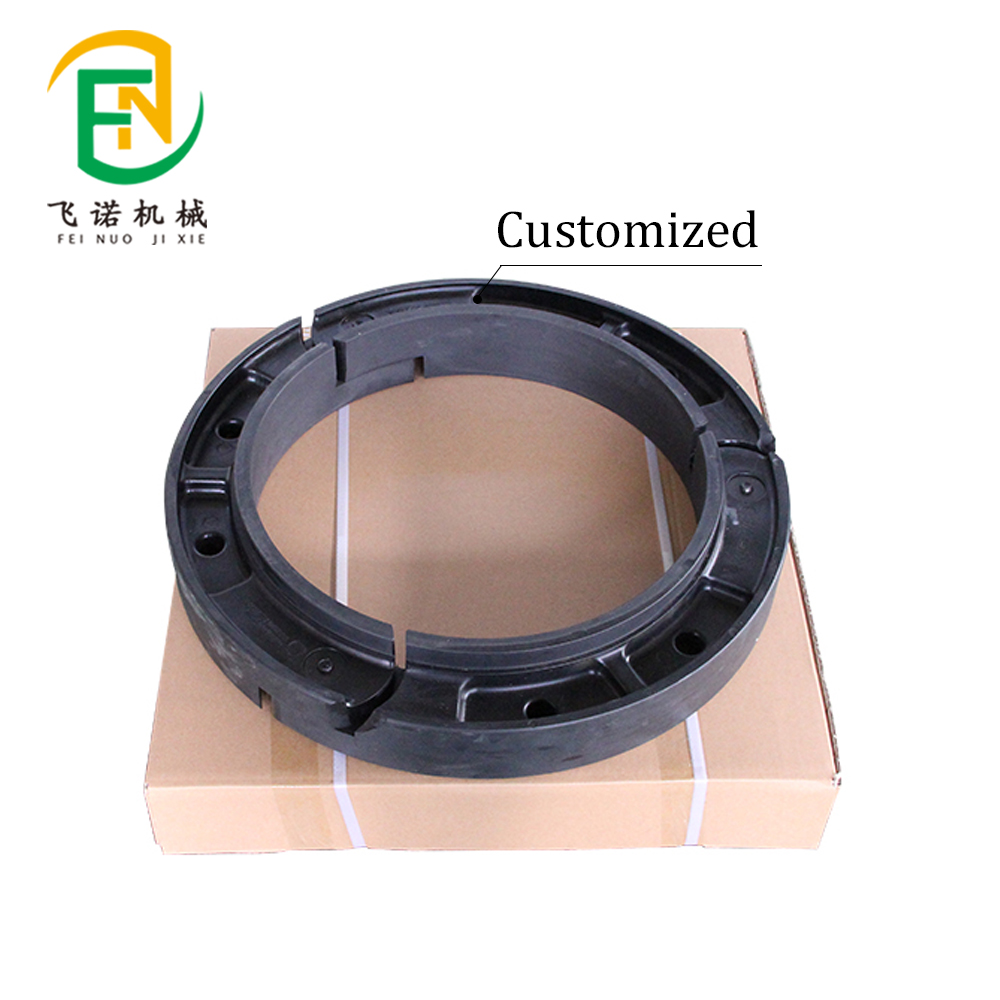

Inspired by this, engineers have begun incorporating run flat inserts—adaptations of the tire’s internal support concept—into sports flooring panels. These inserts are not rubber tires, of course, but composite materials arranged in modular formats. Their role is similar: maintain form and function under sudden stress.

In high-traffic facilities like professional gyms or multi-use stadiums, flooring undergoes constant physical stress. Traditional materials may warp, lose elasticity, or degrade unevenly. But with run flat-inspired inserts embedded beneath the surface, the flooring remains responsive and even, preserving performance and safety.

These inserts act like suspension systems, dispersing load and returning energy efficiently. Just as a vehicle can continue moving across rugged terrain, athletes can maintain momentum and control without flooring breakdown or performance lag.

Engineering Champions: Athlete-Centric Flooring Design Inspired by Tire Technology

Athletes train and compete under extreme conditions, demanding peak performance from every element of their environment. Flooring isn’t just a backdrop; it’s a co-performer. When engineered with the same principles that guide run flat all terrain tires, sports flooring becomes a precision tool.

One example is adaptive firmness—surfaces that respond differently to varied loads and movements. Tire treads do this automatically on off-road terrain, adjusting to uneven surfaces. Now, flooring systems are being designed to offer targeted responsiveness: firmer in high-impact areas, softer in landing zones. This helps reduce injury risk while supporting explosive performance.

Moreover, the modular design of run flat inserts allows for quick replacement of worn areas without overhauling the entire floor, ensuring longevity and optimal training conditions year-round.

Sustainability and Endurance: Materials That Go the Extra Mile

Modern athletic facilities are increasingly focused on sustainability. Here too, inspiration from run flat all terrain tires is transforming sports flooring. Just as all-terrain tires are developed with wear-resistant compounds that maximize lifespan, sports flooring materials are now being crafted for durability and environmental responsibility.

Recyclable elastomers, bio-based polymers, and long-life composite inserts are replacing traditional synthetics. These materials echo the lifecycle-thinking behind tire manufacturing, where every layer is engineered for endurance.

The result is a new class of flooring that not only performs at elite levels but also aligns with global sustainability goals—flooring that can literally and figuratively go the extra mile.

Case Studies: Where Tire Tech Meets the Sports Arena

The real-world impact of this technology can be seen in forward-thinking institutions. Several Olympic training centers in Europe have begun installing courts with run flat-inspired modular bases. These systems are praised for their shock dispersion and joint protection, particularly during high-volume, repetitive drills.

In the United States, some military-grade athletic facilities—designed for both physical training and combat-readiness simulations—have integrated flooring with impact zones modeled after the layered reinforcements of run flat all terrain tires. These spaces accommodate heavy-duty gear, rapid movements, and extreme wear without degrading the surface.

Even elite basketball programs are exploring customizable court sections using interchangeable run flat inserts to match training intensity and reduce injury over long seasons.

The Future of High-Performance Flooring Systems

As innovation accelerates, the bond between vehicle and venue grows stronger. Smart sports flooring embedded with sensors—monitoring pressure, movement, and fatigue—will likely take cues from telemetry systems used in advanced tire technology. Real-time feedback, adaptive surface zones, and AI-driven material response could all become standard features.

But no matter how far technology advances, the inspiration from run flat all terrain tires will remain foundational. Their legacy is more than rubber and steel—it’s the idea that resilience, reliability, and performance can be engineered into every layer.

For athletes chasing greatness, that kind of support is not a luxury—it’s a necessity. And thanks to lessons from the road, sports flooring is finally rising to meet them, one engineered step at a time.