| Property | Test Method | Unit | Value |

| Density | 1S0 1183-1:2012 | g/cm3 | 0.93-0.98 |

| Compression Strength (25%) | 1S0 604:2002 | MPa | ≥35 |

| Tensile Strength at Break | 1S0 527-2:2012 | MPa | ≥24 |

| Elongation at Break | 1S0 527-2:2012 | % | ≥280 |

| Dynamic Friction Coefficient | ASTM D1894 | – | ≤0.18 |

| Notched lmpact Strength (Charpy) | IS0 179-1:2010 | Kym2 | ≥100 |

| Vicat Softing Point | IS0 306:2004 | ℃ | ≥80 |

| Hardness Shore-D | IS0 868:2003 | Shore D | ≥60 |

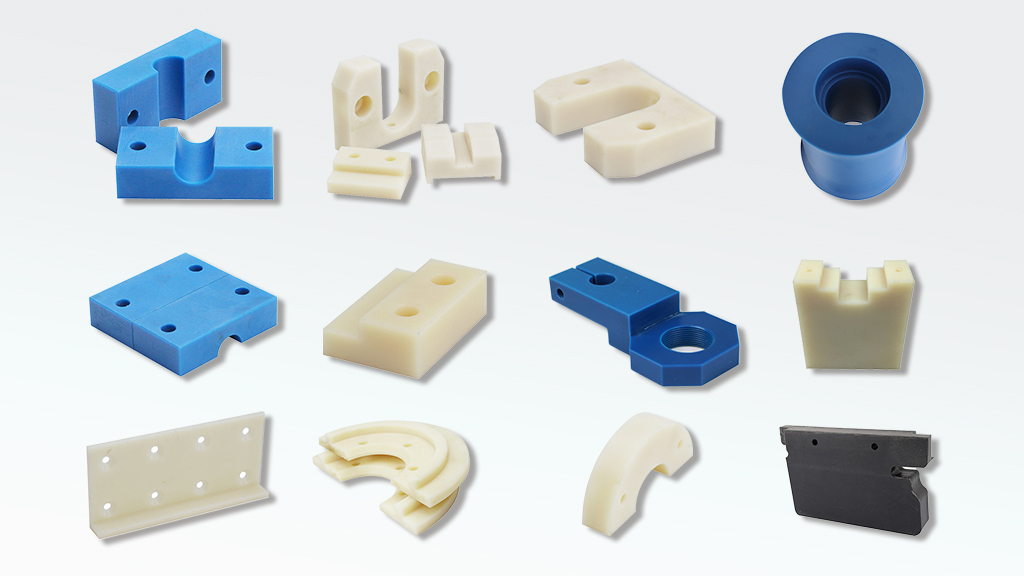

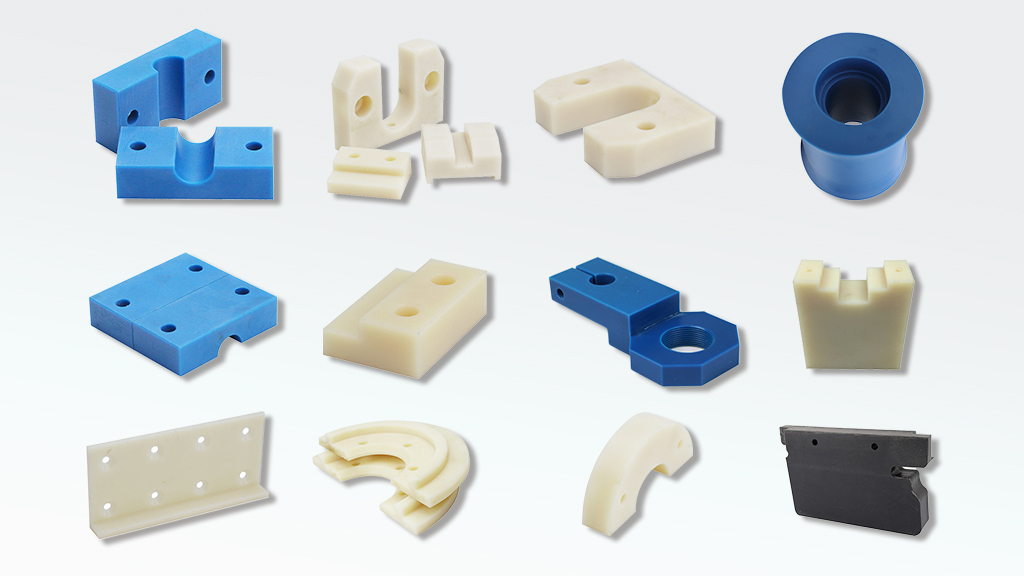

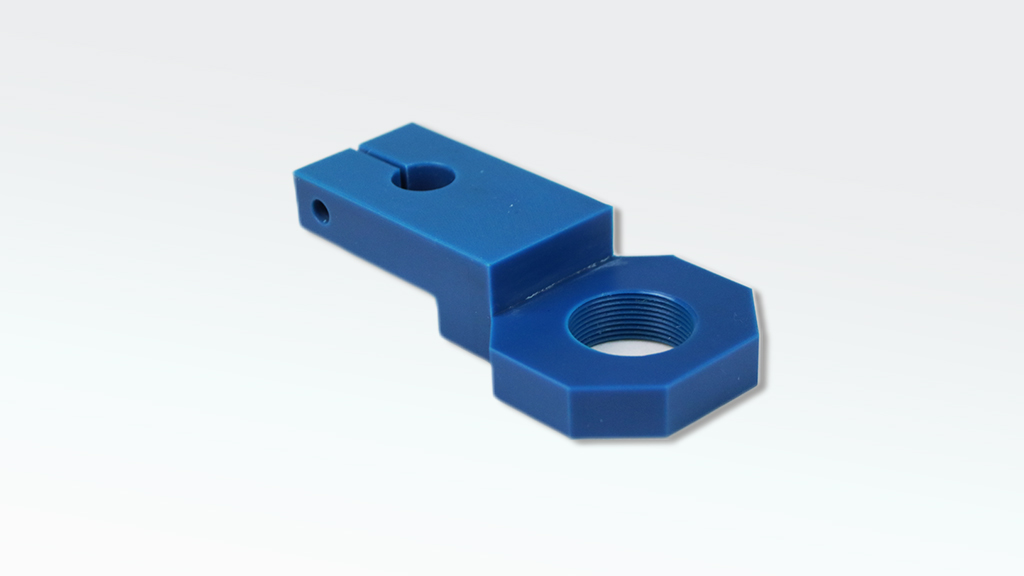

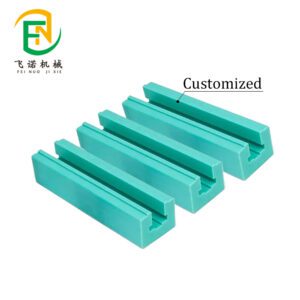

Sliding pads and wear pads are an important product for reducing friction and protecting surfaces. They are widely used in a variety of industries and fields, including machine building, automotive industry, aerospace, construction engineering, etc. The following is the product introduction of sliding pad and wear pad, highlighting the product characteristics:

Slide Pad Wear-Resistant Pad Characteristics:

◉ Superior high impact strength

◉ Low co-efficient of friction

◉ Shock and noise absorption

◉ Excellent self-lubrication

◉ Good chemical resistance

◉ Excellent UV stability-highly suited to the harsh climate

◉ Temperature resistant (-200℃ to + 80 ℃)

◉ 100% recyclable

◉ Does not rot, split or crack

Slide Pad Wear-Resistant Pad Applications:

◉ Fender Panel (Frame) Face Pads

◉ Rubbing Strips

◉ V-fender Shields

◉ Lock Entrance and Wall Protection

◉ Bridge Buttress Protection

◉ Beltings on Workboats

There are no reviews yet.