| name | professional high precision plastic injection parts |

| color | Universal Size And Custom Size |

| material | white, black, green, nature,blue,yellow,etc |

| mould cavity | ABS.PMMA,PC,PP. PEEK,PU,PA,PA+GF,POM,PE,UPE,PTFE etc |

| runner system | single cavity & multi cavity |

| equipment | hot runner and cold runner |

| mould material | CNC, EDM, cutting off machine, plastic machinery etcP20/718H/ S136H/ S136 hardened/ NAK80 |

| injection machine | 88T 90T 120T 168T200T 380T,420T,1200T |

| mould life | 500000-5000000 shots as per customers’requirement |

| Size | 5-1000mm,or customized |

| tolerance | 0.01mm |

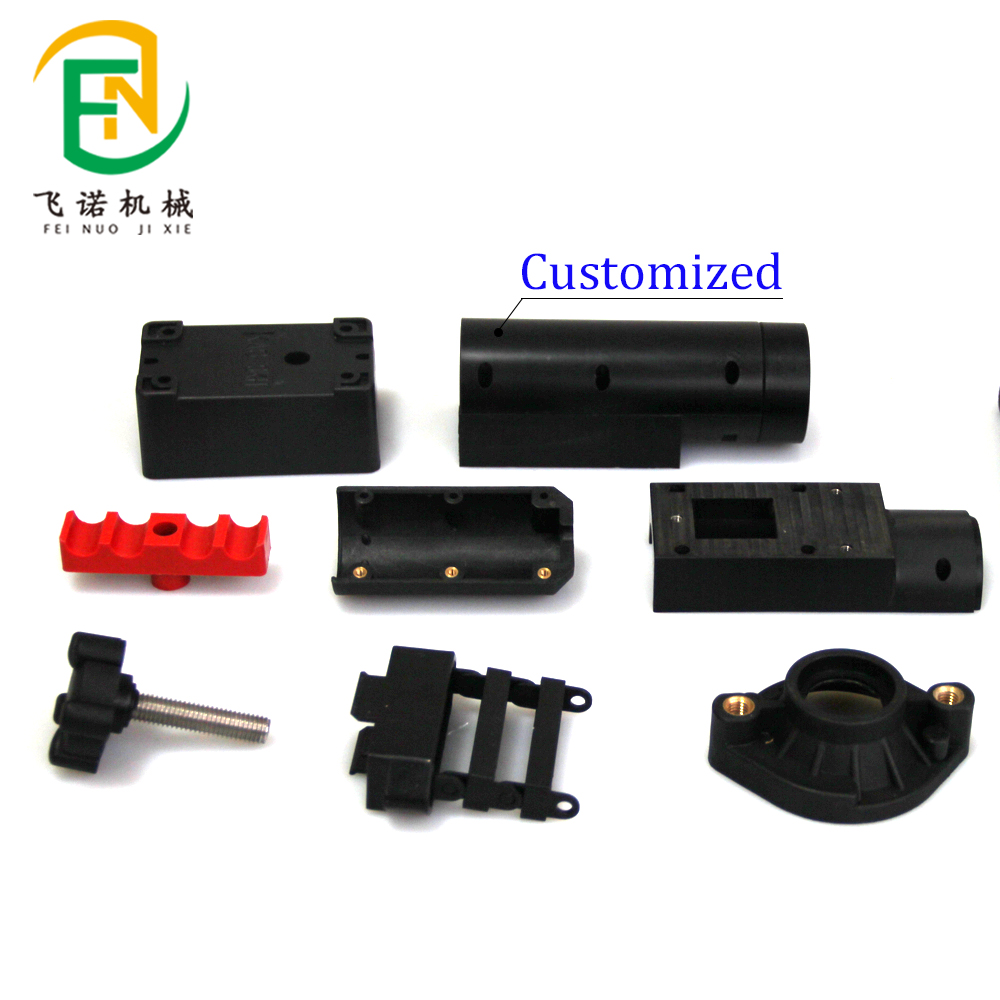

| shape | as per your drawing or the sample |

| certification | 1S09001 and relate whole set professional test report |

| free sample | available |

| advantage | one stop procurement |

| Application field | Various plastic injection molded parts for various industrial and automotive applications |

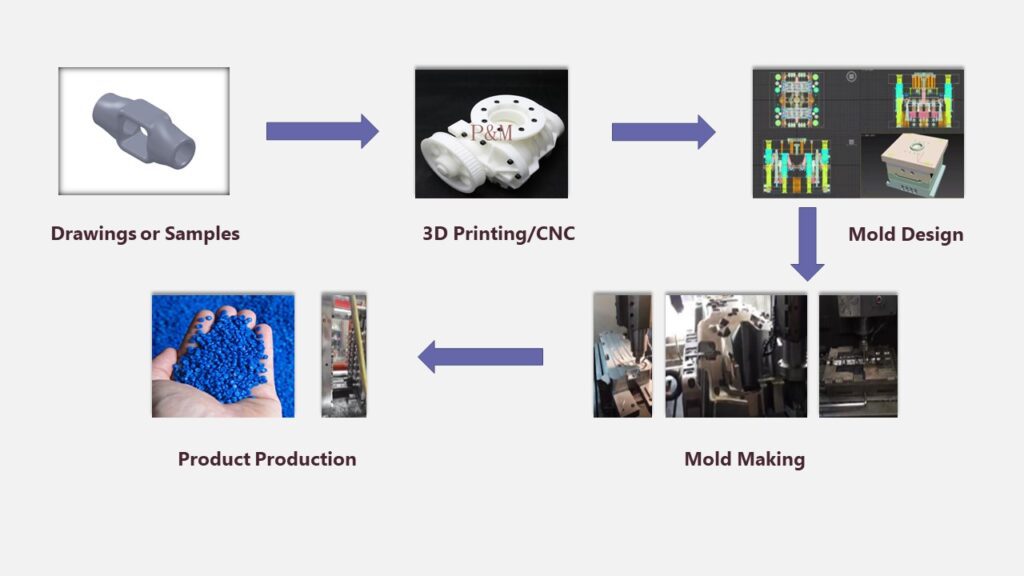

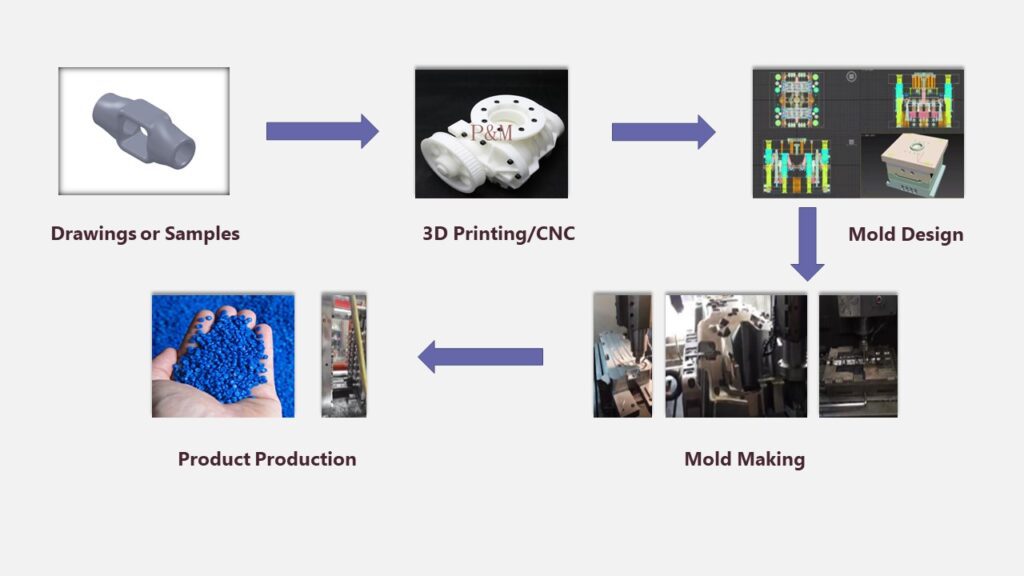

| lead time | 15-30 days for mould, plastic products according to quantity |

Provide Free Product Design Modification Advice

Provide Similar Sample photo

ABS shell injection molding products are widely used in various fields, including electronic products, household appliances, auto parts, industrial equipment, medical equipment and so on. They can be used as protective housings, outer packaging, accessories, etc., to provide structural support, durability, and exterior decoration. Through the injection molding process, ABS plastics can manufacture complex shell structures in a fast, efficient and cost-effective manner. Injection molding production can also achieve large-scale production, improve production efficiency and product quality consistency.

There are no reviews yet.