- February 20, 2025

- Posted by: feinuojixie

- Category: Injection Molding News

In the dynamic landscape of modern manufacturing, injection molded parts have emerged as the cornerstone of countless industries. These components, crafted through a highly efficient and precise manufacturing process, play a pivotal role in bringing innovative products to life.

The Vast Array of Injection Molded Parts

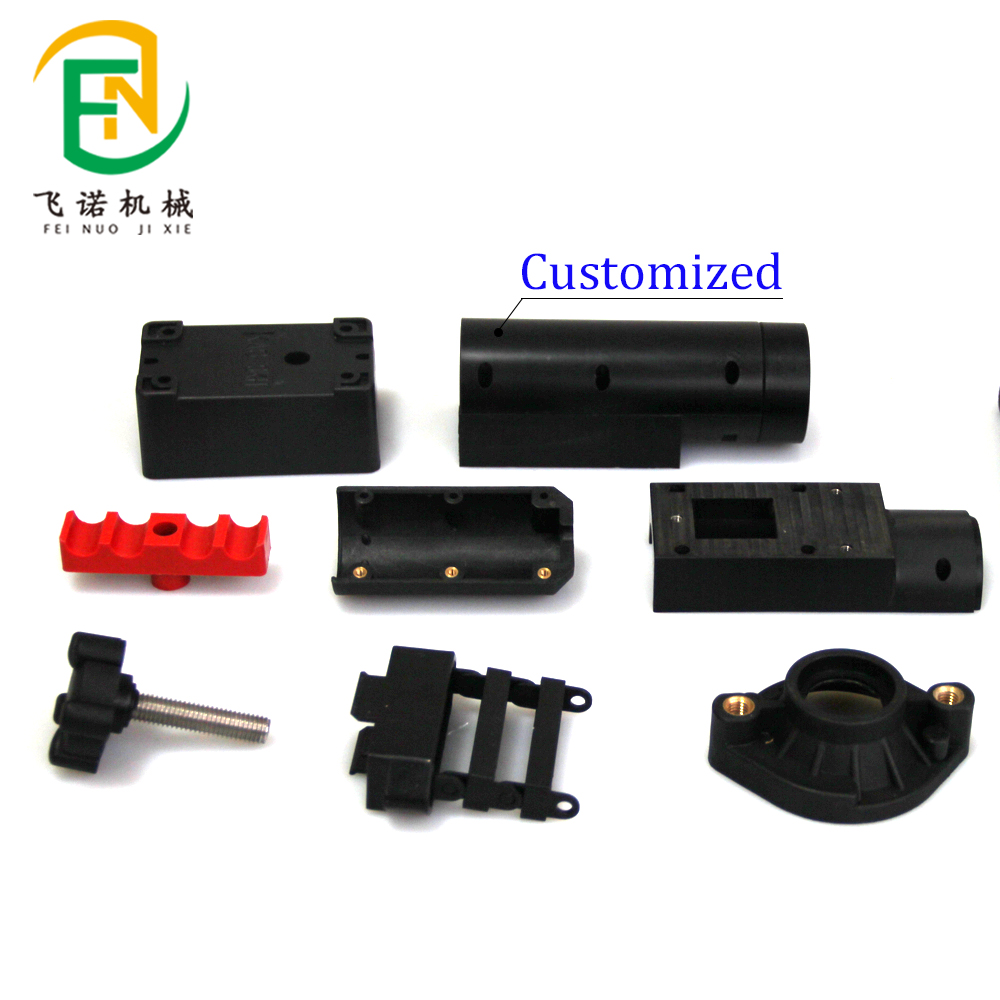

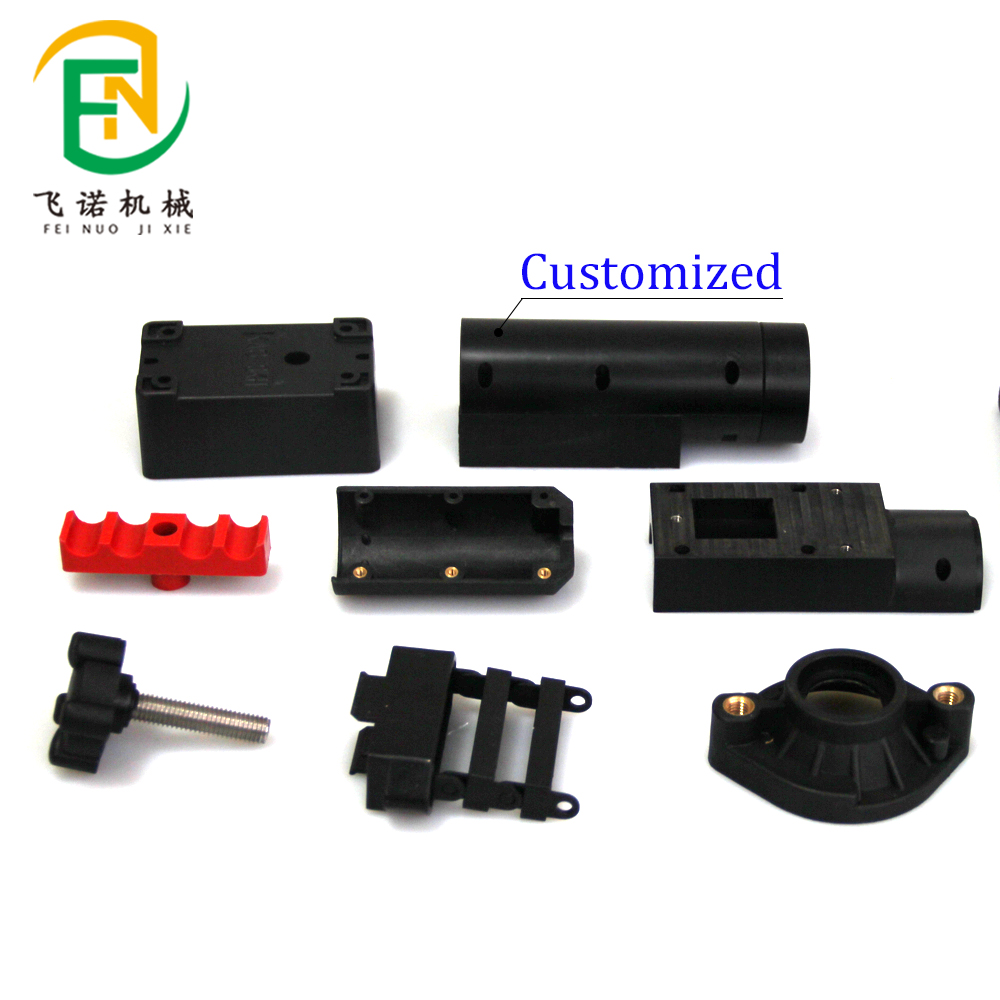

Our inventory boasts an impressive collection of injection molded part. From small, intricate plastic components that are barely visible to the naked eye, such as those used in micro – electronics, to large – scale, robust parts for industrial machinery, we have it all. There are consumer – facing items like smartphone cases, which require a perfect blend of aesthetics and functionality, and automotive interior parts that demand high – quality finishes and durability. Additionally, we offer a wide variety of connectors, housings, and brackets, each designed to meet specific engineering requirements.

The Incomparable Advantages of Injection Molded Parts

Cost – Efficiency

Injection molding is a cost – effective manufacturing method, especially for high – volume production. Once the initial mold is created, the cost per unit decreases significantly as the production quantity increases. This makes it an ideal choice for companies looking to scale up their production without breaking the bank.

High Precision

The injection molding process allows for an extremely high level of precision. Tolerances can be maintained within a very tight range, ensuring that each part is identical to the next. This precision is crucial for applications where components need to fit together perfectly, such as in complex mechanical assemblies.

High Production Efficiency

With the ability to produce multiple parts in a single cycle, injection molding offers high production speeds. Automated injection molding machines can operate continuously, churning out a large number of parts in a relatively short period, thus meeting the demands of fast – paced industries.

Diverse Application Fields of Injection Molded Parts

Automotive Industry

In the automotive sector, injection molded parts are everywhere. They are used in engine components, interior trims, and exterior body panels. For example, lightweight plastic bumpers made through injection molding not only reduce the vehicle’s weight but also enhance fuel efficiency.

Electronics Industry

In the electronics world, injection molded parts are essential for manufacturing everything from computer casings to small electronic components. The precision of injection molding ensures that these parts can house delicate electronic circuits safely and securely.

Medical Industry

In the medical field, injection molded parts are used in a wide range of applications, from disposable syringes to complex surgical instruments. The high – quality materials and precision manufacturing capabilities of injection molding make it possible to produce medical devices that meet strict regulatory requirements.

Custom Injection Molding Services

We understand that every project is unique, which is why we offer comprehensive custom injection molding services. Our process begins with in – depth consultations to understand your specific requirements. Our team of experienced engineers then designs the mold, taking into account factors such as part geometry, material properties, and production volume. Once the mold is created, we conduct rigorous testing to ensure its functionality and quality. The advantage of our custom service is that it allows you to have parts that are tailored exactly to your needs, giving you a competitive edge in the market.

Stringent Quality Control and Certifications

Quality is at the heart of everything we do. We have a strict quality control system in place, which involves inspecting every stage of the injection molding process. From the raw materials to the final product, we ensure that each part meets the highest standards. Moreover, we hold various international certifications, such as ISO 9001, which is a testament to our commitment to quality management.

Client Success Stories

Let’s take a look at some of our client success stories. One of our automotive clients was struggling with the high cost of metal components for their vehicle interiors. By switching to our injection molded plastic parts, they were able to reduce costs by 30% without sacrificing quality. Another electronics company needed a highly precise housing for their new product. Our custom injection molding service helped them create a housing that not only protected their electronics but also enhanced the product’s overall aesthetics, leading to a significant increase in sales.

Future Prospects

The future of injection molded parts looks bright. With the continuous development of materials science, we can expect to see even more advanced materials being used in injection molding. For example, biodegradable plastics are becoming increasingly popular, which will open up new opportunities in industries such as packaging and consumer goods. Additionally, the integration of artificial intelligence and machine learning in the injection molding process will lead to more efficient production and better – quality control.

Conclusion

In conclusion, our extensive range of injection molded parts offers a world of possibilities for manufacturers across various industries. Whether you need cost – effective solutions, high – precision components, or custom – made parts, we have the expertise and resources to meet your needs. We encourage you to explore our product range and discover how our injection molded parts can add value to your products and projects. Let’s work together to shape the future of manufacturing.