- May 20, 2025

- Posted by: feinuojixie

- Category: Injection Molding News

In an age where safety, reliability, and performance are non-negotiable, run flat insert have emerged as a quiet yet critical revolution in tire technology. Whether navigating the blistering speeds of a racetrack or crawling over jagged rocks in a remote desert, these components ensure that vehicles can keep moving—even when the unexpected strikes. Unlike traditional tires that can quickly become a liability upon puncture, a run flat insert provides structural integrity that allows the tire to support the vehicle’s weight and maintain functionality for extended distances.

The growing demand for run flat insert is not limited to elite motorsports or military applications. Today, they are gaining popularity across a broad spectrum of industries, including emergency services, adventure tourism, construction, and even personal transport. Their unique value proposition—safety without sacrifice—makes them an attractive choice for those who operate in unpredictable or high-risk environments. In this blog, we’ll explore how run flat insert are engineered, where they’re being used, and why their role is expanding so rapidly across different terrains and applications.

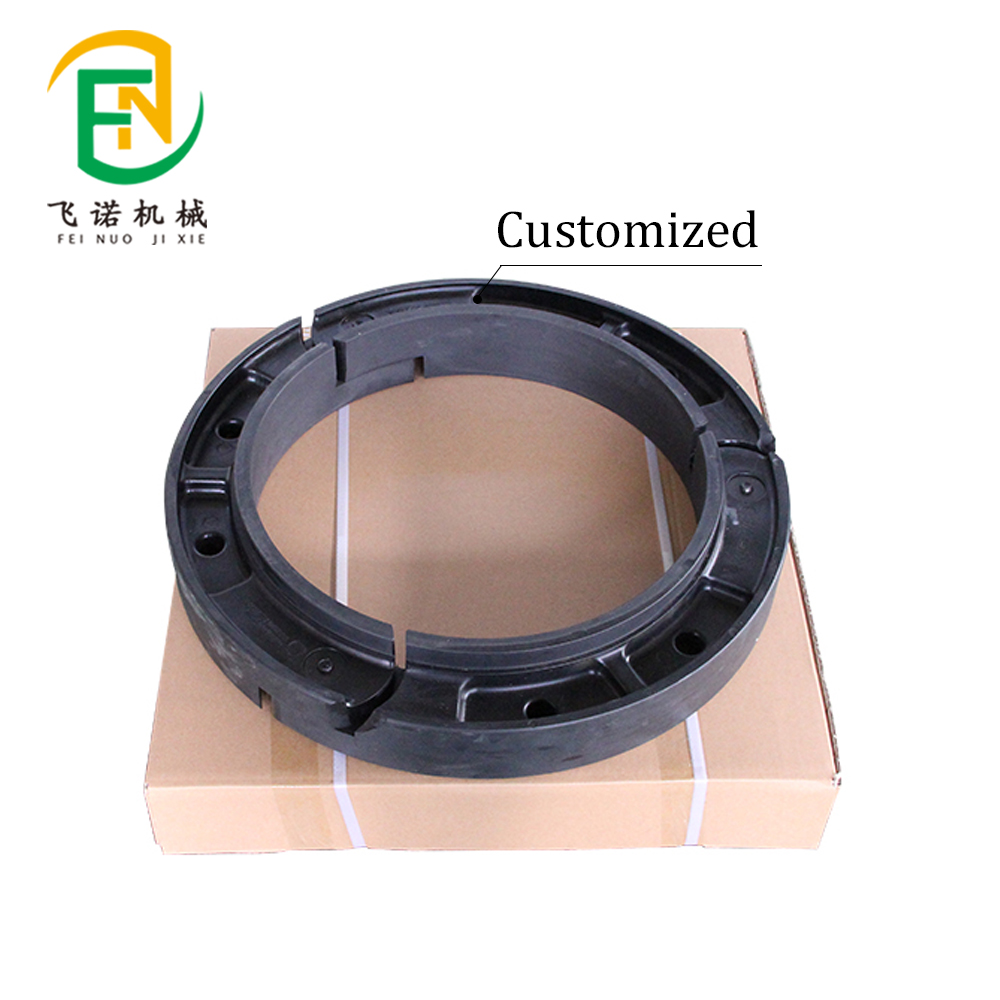

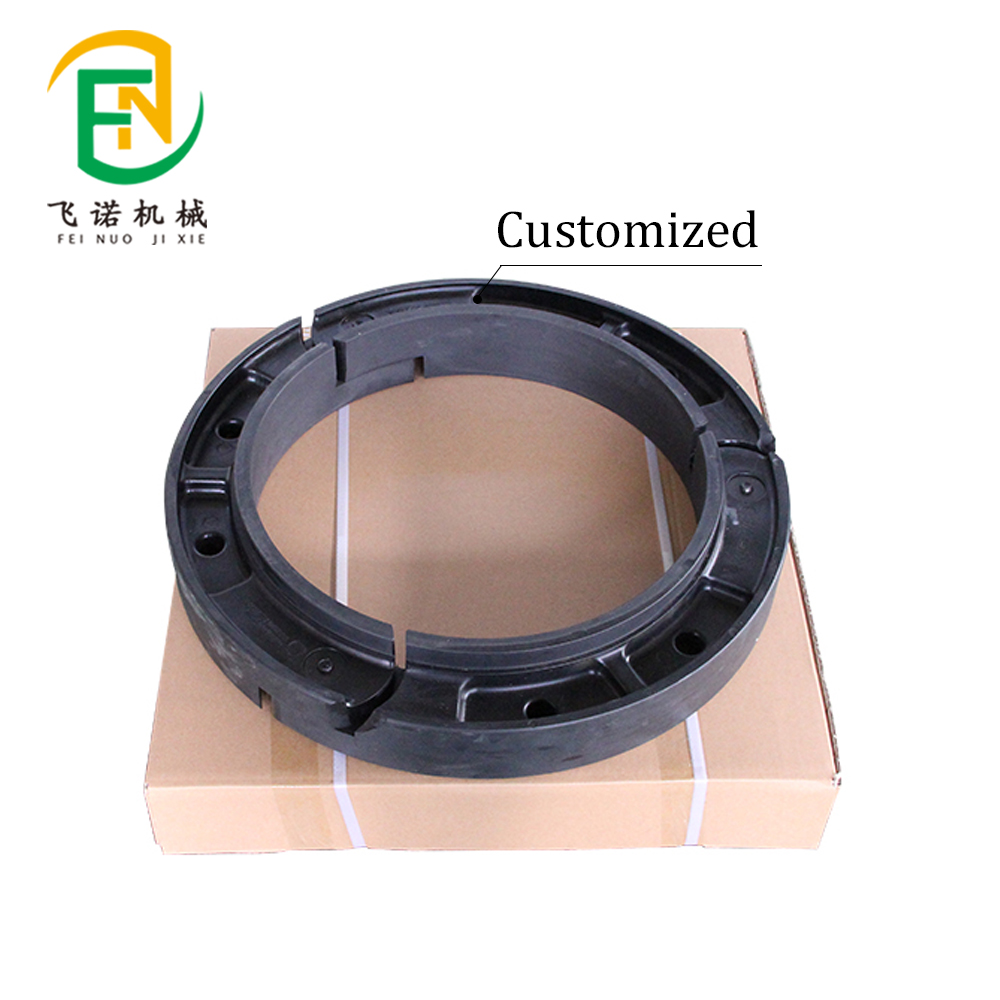

The Anatomy of a Run Flat Insert: How It Works and What It Does

At the heart of every run flat insert lies a deceptively simple concept: structural support in the absence of air pressure. Unlike traditional pneumatic systems that rely solely on inflation, a run flat insert sits inside the tire and provides a physical layer of support when the tire is punctured or deflates. This allows the vehicle to keep moving—often for tens of miles—at a reduced but controlled speed, giving drivers time to reach a safe location or complete a mission.

Most run flat insert are constructed using high-strength polymers or reinforced rubber compounds. Some are engineered to support the full vehicle load, while others are designed to maintain shape and directional control. In either case, they significantly reduce the chance of a tire blowout leading to loss of control. For industries where time, safety, and stability are critical, understanding the anatomy of a run flat insert is the first step toward smarter mobility solutions.

Run Flat Insert in Motorsports: Safety and Speed Without Compromise

In the fast-paced world of motorsports, fractions of a second can determine victory or defeat. Tire performance is paramount, and so is driver safety. This is where run flat insert play an invaluable role. In high-speed scenarios, a punctured tire can lead to catastrophic crashes. A run flat insert, however, maintains structural integrity long enough for the driver to either complete a lap or safely pull into the pit.

Many professional racing teams now use custom-engineered run flat insert that are lightweight, thermally stable, and specifically tuned for the vehicle’s suspension and tire characteristics. These inserts not only enhance safety but also reduce the risk of race-ending incidents. As technology improves, motorsport applications continue to drive innovation in insert design, making them faster, stronger, and more efficient.

Off-Road Adventures: Why Run Flat Insert Are a Game Changer for Rugged Terrains

Off-road drivers face unpredictable challenges—from jagged rocks and deep mud to sudden drops and sharp terrain transitions. For these adventurers, a tire failure in the wrong place can mean being stranded miles from help. Run flat insert eliminate that risk by providing a built-in safety net that keeps the vehicle rolling even after serious tire damage.

Whether it’s for recreational off-roading, overlanding, or expedition-level travel, run flat insert offer peace of mind. They allow drivers to traverse remote regions without the constant worry of tire integrity. In rough terrains where help might be hours—or days—away, the ability to continue driving despite a puncture can be the difference between a memorable adventure and a dangerous situation.

Defense and Security: The Strategic Importance of Run Flat Insert in Military Vehicles

For military and security vehicles, mobility is a mission-critical factor. A disabled vehicle in a hostile environment not only endangers personnel but can also jeopardize entire operations. This is why run flat insert are widely adopted in armored personnel carriers, tactical trucks, and reconnaissance vehicles. Their ability to maintain mobility after tire damage is not just convenient—it’s life-saving.

Modern run flat insert for military applications are built to withstand extreme stress, including ballistic damage and high-impact conditions. These inserts are often paired with beadlock systems to prevent tire separation and ensure continued control. In scenarios where every second counts and failure is not an option, run flat insert provide a tactical edge that enhances operational success and survivability.

Commercial and Civilian Vehicles: Expanding Applications Beyond Extreme Conditions

What was once exclusive to military and motorsport circles is now filtering into everyday transportation. Commercial fleets, armored bank vehicles, police cars, and even high-end SUVs are being equipped with run flat insert. The logic is simple: safety should not be optional, especially when transporting people, valuables, or perishable goods.

Run flat insert allow businesses to reduce downtime and increase operational efficiency. For emergency response teams, they ensure vehicles can reach their destination regardless of tire status. For families, they offer the assurance that a blowout on the highway won’t result in a dangerous roadside emergency. As more manufacturers recognize their value, run flat insert are becoming a standard rather than an exception.

Choosing the Right Run Flat Insert: What to Look For

With a growing market comes a wide variety of run flat insert products—each with its own strengths and specifications. Choosing the right insert involves more than matching size and shape. Key considerations include the type of vehicle, maximum load capacity, operating temperature range, material composition, and ease of installation.

Buyers should also look for regulatory certifications and field-tested performance metrics. For off-road or military use, reinforced materials and durability under stress are essential. For commercial fleets, longevity and serviceability are top priorities. Understanding these variables can help users select a run flat insert that fits both their vehicle and their operational needs.

The Future Road: Innovations Driving the Next Generation of Run Flat Insert

As demand increases, so does the pace of innovation. Manufacturers are developing next-generation run flat insert that are lighter, more resilient, and more adaptable to different wheel systems. Some feature modular designs that allow quick replacement in the field. Others incorporate smart sensors that monitor pressure and structural integrity in real time.

There’s also a growing interest in sustainability, with companies exploring recyclable materials and energy-efficient manufacturing methods. As electric vehicles rise in popularity, new designs must also consider the added weight and unique load distribution of EV platforms. In every case, the future of run flat insert lies in intelligent engineering and cross-industry collaboration.

Why Run Flat Insert Are No Longer Optional in High-Demand Environments

From high-octane racetracks to unforgiving off-road trails and critical military zones, run flat insert have proven their worth in the most demanding environments. Their ability to maintain vehicle mobility, protect passengers, and minimize downtime makes them an essential component of modern tire systems.

As technology advances and the use cases expand, run flat insert are quickly transitioning from niche add-ons to mainstream must-haves. Whether you’re a fleet manager, an off-road enthusiast, or a defense contractor, investing in the right run flat insert is no longer just smart—it’s necessary. In a world where the road ahead is never guaranteed, run flat insert offer the confidence to keep going, no matter what lies beneath your wheels.