- May 14, 2025

- Posted by: feinuojixie

- Category: Injection Molding News

When you’re cruising down the highway at 70 miles per hour, the last thing you want is a flat tire. Yet punctures happen—sometimes in the worst possible places. What if you could keep driving even after your tire has been compromised? That’s where run flat insert step in. Hidden inside the tire, this innovation acts like an invisible shield, providing critical support in moments of crisis. While often overshadowed by more visible components of automotive technology, the run flat insert plays a crucial role in ensuring safety, control, and continuity on the road. This article dives deep into how this clever piece of engineering works wonders behind the scenes and why it’s becoming a go-to solution in demanding driving environments.

The Basics of Run Flat Insert

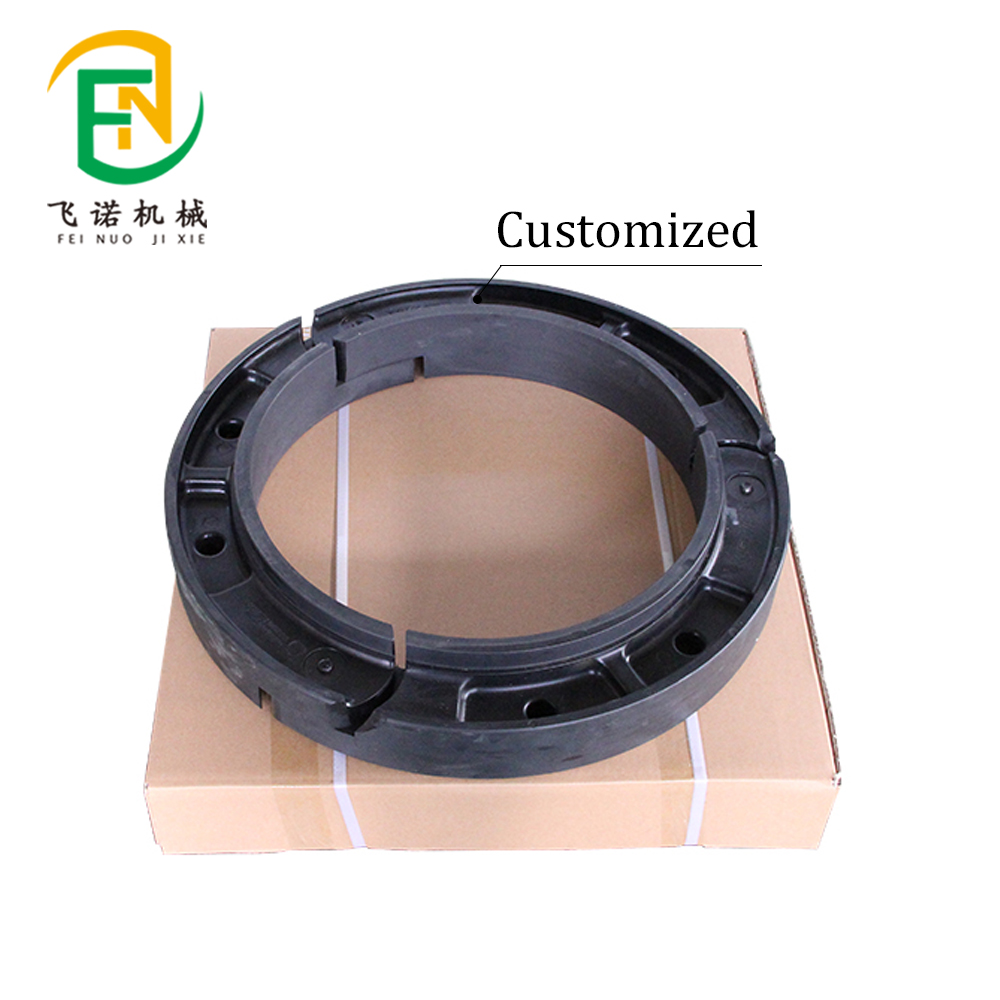

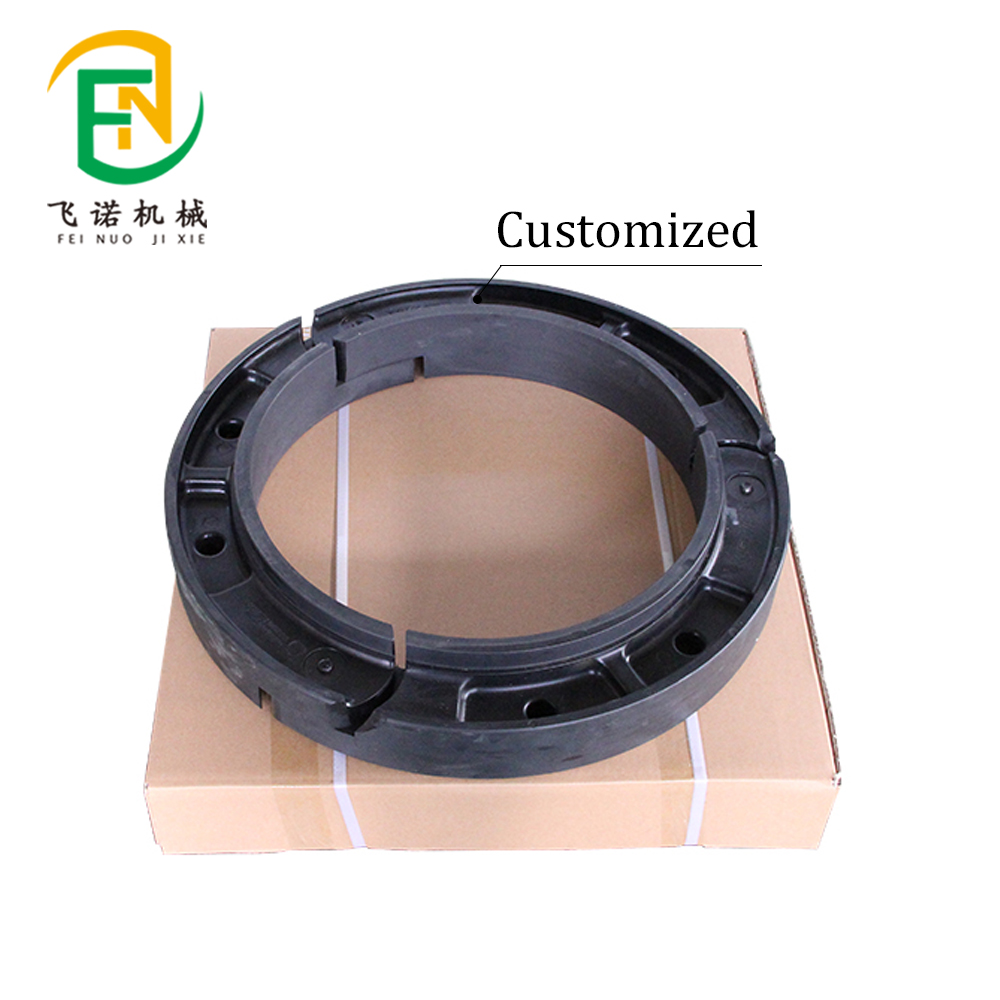

A run flat insert is a reinforced ring or liner placed inside a tire that allows a vehicle to continue operating after a loss of air pressure. Unlike traditional tires that go limp when punctured, the insert bears the load of the vehicle temporarily—giving the driver time to find a safe place to stop or reach a service station. This device is especially valuable in situations where stopping immediately could be dangerous or inconvenient. With a run flat insert, drivers often have 50 to 100 kilometers of extended driving range after a puncture, depending on vehicle weight and road conditions.

How Run Flat Insert Maintain Driveability After a Puncture

The key to a run flat insert is its ability to support the tire sidewall when air pressure drops to zero. When a tire is deflated, the insert acts as a mechanical support ring, keeping the tire’s shape and allowing it to roll without collapsing onto the rim. Some inserts are designed to expand and press against the inner tread area to prevent rim damage and maintain tire rotation. The system reduces the risk of losing control at high speeds and protects the vehicle’s wheel and suspension components from further damage.

Key Materials Used in Run Flat Insert

Durability under pressure is essential, and that starts with materials. A typical run flat insert is made from high-performance rubber blends, reinforced polymers, or thermoplastic elastomers. These materials are selected for their ability to withstand extreme temperatures, friction, and compression forces. Some advanced versions include embedded heat-dissipating elements to prevent overheating during extended run-flat operation. The right material not only maintains structural integrity but also keeps the insert lightweight enough to avoid impacting tire balance and overall vehicle performance.

Types of Run Flat Insert Systems in the Market

There are several designs of run flat insert, each tailored to specific needs:

-

Self-supporting insert: Built directly into the tire structure, this type uses rigid sidewall reinforcement and an internal liner. It requires specially designed tires and is popular in performance and luxury vehicles.

-

Auxiliary-supported insert: Installed between the wheel and tire, this type uses a separate insert ring mounted on the rim. It can be used with standard tires and is favored in off-road and military vehicles.

-

Hybrid designs: These combine elements of both systems, offering a balance of comfort, performance, and extended mobility. Hybrid solutions are gaining popularity in armored civilian vehicles and emergency response fleets.

Each system offers trade-offs in terms of cost, ride comfort, and repairability, but all serve the same core function—ensuring driveability after a puncture.

Installation and Compatibility with Standard Rims

A major concern for many users is whether a run flat insert can be retrofitted to existing wheels. The answer depends on the system. Some auxiliary insert models are compatible with standard rims, while others require dedicated wheels or tires. Installation typically involves specialized tools and trained technicians to ensure proper placement and balance. Although installation costs can be higher than regular tire services, the long-term benefits in safety and mobility often outweigh the initial investment. Regular inspection and occasional replacement are recommended, especially for vehicles used in high-stress conditions.

Performance Benefits: Safety, Stability, and Peace of Mind

The most obvious benefit of a run flat insert is safety. Drivers can maintain control during sudden air loss, avoid hazardous roadside tire changes, and reduce exposure to accidents. But the advantages go beyond emergencies. The insert helps stabilize the tire, reducing vibrations and maintaining steering responsiveness during partial deflation. It also adds a level of psychological security—knowing that you won’t be stranded by a flat in the middle of nowhere or during peak traffic hours. For logistics and emergency service vehicles, this reliability is invaluable.

Run Flat Insert vs. Run Flat Tire: What’s the Difference?

The terms “run flat tire” and “run flat insert” are often used interchangeably, but they refer to different solutions. A run flat tire is a complete tire with reinforced sidewalls designed to support the vehicle when deflated. In contrast, a run flat insert is a separate component that can be added to a standard tire or wheel setup. Inserts offer more flexibility in customization, easier replacement, and in some cases, better performance under heavy loads. For military and off-road use, inserts are often the preferred choice due to their rugged durability and modular design.

Applications in Military, Motorsport, and Everyday Vehicles

The run flat insert was originally developed for military and tactical applications, where vehicle mobility is critical even under fire or over hostile terrain. Over time, its use expanded to motorsports, where every second counts and tire failure could mean the end of a race. Today, high-end sedans, SUVs, and armored transport vehicles also rely on insert technology to meet safety and performance expectations. With growing demand for vehicles that combine luxury, security, and reliability, the insert’s role continues to evolve across multiple industries.

Future Trends in Run Flat Insert Technology

Innovation never stops. The next generation of run flat insert is expected to feature lighter composite materials, better heat dissipation, and improved integration with digital tire pressure monitoring systems (TPMS). Some companies are experimenting with smart inserts that can alert drivers in real time about structural damage or performance thresholds. Others are researching self-healing materials or adaptive geometry that can adjust to different puncture scenarios. As electric and autonomous vehicles become more common, the need for uninterrupted mobility will only drive further advancements.

Small Device, Big Impact

Though small and often invisible, the run flat insert is a powerful piece of technology. It bridges the gap between safety and convenience, allowing drivers to maintain control even when the unexpected happens. As more drivers—and industries—realize the benefits of staying mobile in all conditions, the run flat insert is poised to become a standard, not just a luxury. Understanding how it works and where it’s headed gives us a glimpse into the smarter, safer future of driving.