- May 19, 2025

- Posted by: feinuojixie

- Category: Injection Molding News

In today’s fast-moving world, vehicle reliability is no longer just a luxury—it’s a necessity. Whether it’s a military vehicle navigating rugged terrain or a commercial fleet delivering time-sensitive cargo, unexpected tire failure can spell disaster. Traditional tires, even with reinforced sidewalls, offer limited protection against blowouts or punctures. That’s where run flat insert comes into play, changing the way we think about mobility and safety.

A run flat insert is more than just a backup plan—it’s a proactive solution. Designed to keep vehicles moving even after complete air loss, it eliminates the need for immediate roadside intervention. This innovation is rapidly becoming essential for industries that demand uninterrupted performance under the harshest conditions. In this article, we’ll explore the technology, benefits, and future of run flat insert, helping you understand why it’s a game-changer in tire reliability.

What is a Run Flat Insert and How Does It Work?

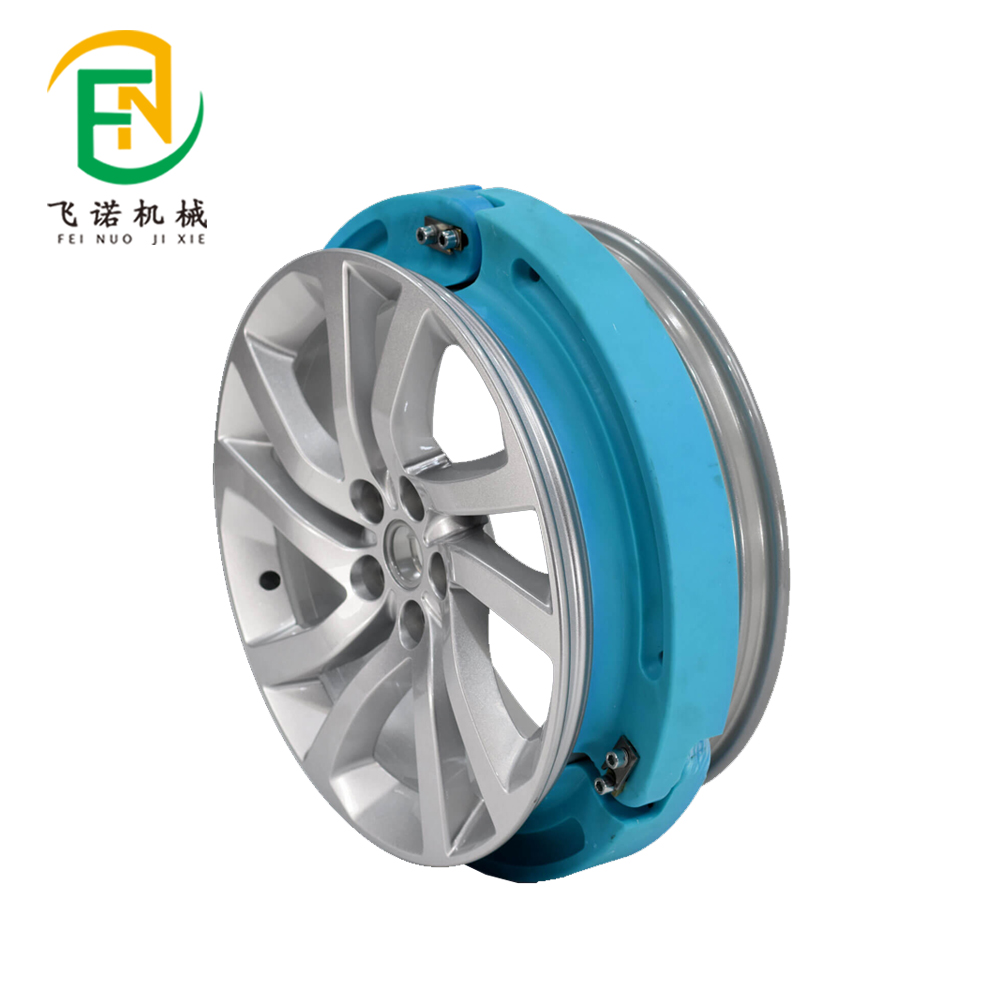

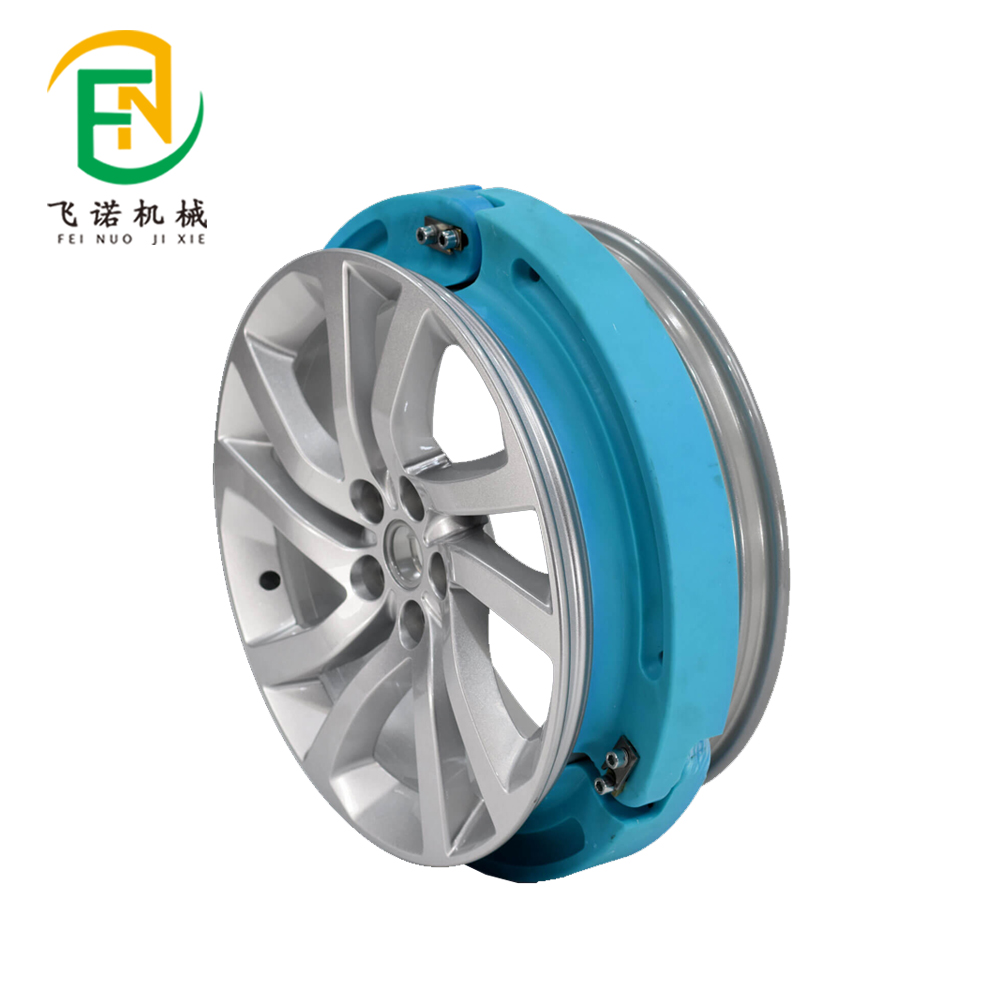

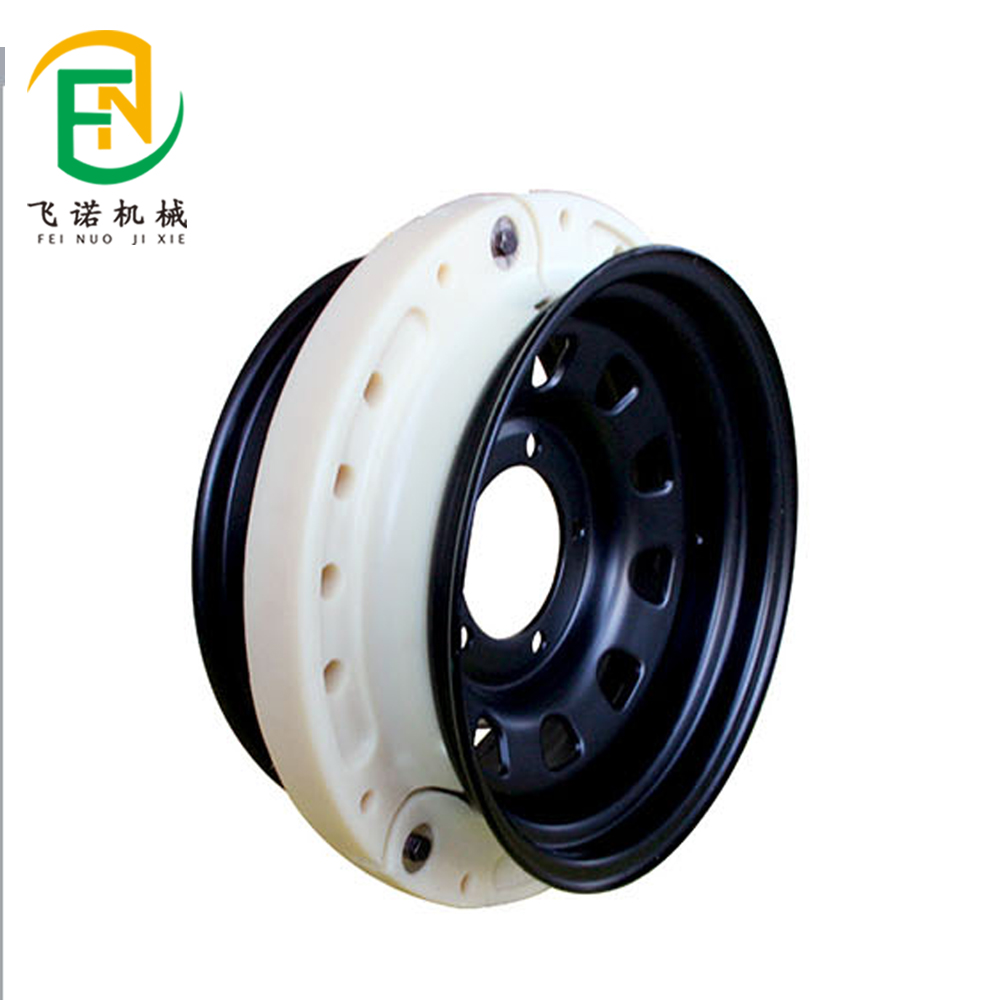

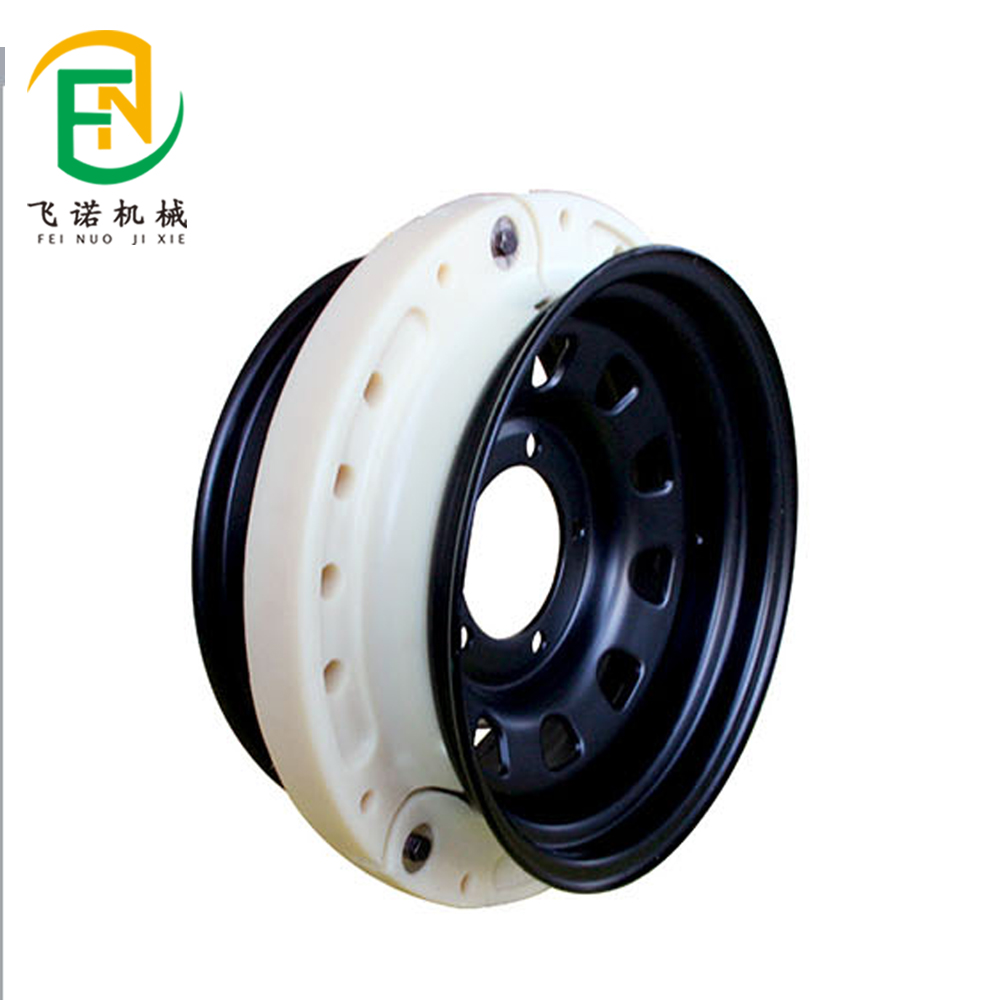

A run flat insert is a specially engineered component installed inside a standard pneumatic tire, designed to maintain vehicle mobility even after a complete loss of air pressure. Unlike run-flat tires that rely on reinforced sidewalls, this insert provides internal structural support, allowing the tire to continue rolling without collapsing.

Typically made from robust materials such as high-density polymer or rubber composites, a run flat insert sits between the wheel and the inner surface of the tire. In the event of a puncture or blowout, the insert bears the vehicle’s weight and preserves tire shape, enabling controlled driving for extended distances—often up to 50 kilometers or more. This capability makes it an ideal solution for mission-critical operations where stopping is not an option.

The Technology Behind the Performance

The effectiveness of a run flat insert lies in its material science and structural engineering. These inserts are crafted from materials that combine flexibility with extreme strength, including reinforced thermoplastics, ballistic-grade rubber, and sometimes even aluminum alloys for heavy-duty applications.

One of the core design elements is the support ring, which absorbs impact and maintains shape under high stress. Advanced models incorporate features for heat dissipation, preventing overheating from the friction generated during pressure-free travel. This blend of properties ensures not only continued mobility but also minimizes damage to the tire and rim.

The latest technological advancements also focus on modular designs that fit a range of tire sizes and vehicle types, making them more accessible and efficient to deploy across various platforms.

Key Benefits of Using Run Flat Insert

Safety and reliability are at the heart of what makes a run flat insert so valuable. The most immediate benefit is continued vehicle mobility after a tire puncture, allowing drivers to reach a safe location instead of being stranded in potentially hazardous environments.

Beyond that, run flat insert reduces downtime by eliminating the need for emergency tire changes on the roadside. This is especially important in environments where safety, timing, or terrain conditions do not allow for a traditional repair.

Other benefits include:

-

Enhanced vehicle control after air loss

-

Compatibility with standard tires and rims

-

Minimal impact on ride comfort

-

Lower long-term maintenance costs compared to run-flat tires

For industries where uptime is critical, such as defense, law enforcement, or logistics, these benefits translate into operational resilience and cost savings.

Applications Across Industries: From Armored Vehicles to Commercial Fleets

Originally developed for military use, run flat insert has now found its way into a wide array of industries. In armored vehicles and tactical transport, it ensures mission continuity even when tires are damaged by shrapnel or debris. For law enforcement and security vehicles, it offers the ability to maintain pursuit or exit high-risk zones without delay.

Mining and construction companies also utilize run flat insert to navigate rough, unpredictable terrain where sharp objects or unstable surfaces can puncture tires. Commercial fleets use them as part of their risk mitigation strategies, particularly for deliveries in remote areas or high-traffic urban zones.

Even luxury automotive brands are exploring this technology to offer enhanced safety without compromising ride quality, especially in premium SUVs designed for both city driving and off-road adventure.

How to Choose the Right Run Flat Insert for Your Vehicle

Selecting the right run flat insert involves understanding your vehicle’s weight, usage, and terrain exposure. For light commercial vehicles, inserts designed for low to moderate payloads and asphalt conditions may suffice. Meanwhile, armored or off-road vehicles require heavy-duty versions that can endure extreme stress and temperature fluctuations.

Key considerations include:

-

Vehicle gross weight and axle load

-

Tire diameter and width

-

Terrain types (urban, off-road, desert, etc.)

-

Operational speed requirements during flat conditions

It’s also critical to ensure the insert is certified and tested under relevant performance standards. Reputable manufacturers often provide detailed compatibility charts and technical support to guide buyers through the selection process.

Installation and Maintenance: What You Need to Know

Installing a run flat insert requires specialized equipment and trained technicians. The process involves removing the tire, fitting the insert onto the wheel, and then reinstalling the tire around it. This ensures a tight and balanced fit to maintain optimal performance.

Once installed, run flat insert requires minimal maintenance, but regular inspections are recommended—particularly after impact events or prolonged high-speed travel on a deflated tire. Signs of wear, deformation, or heat damage should prompt a replacement to maintain full functionality.

Many fleet operators schedule periodic checks as part of routine maintenance, ensuring the system is always ready for emergency use.

Challenges and Considerations Before Adopting Run Flat Insert

Despite its many advantages, there are some challenges to consider before adopting run flat insert. One of the primary concerns is cost—initial investment is higher compared to conventional tires or even some run-flat tire options. However, this cost is often offset by reduced downtime and extended service life.

Another factor is the added weight, which can affect fuel economy slightly, especially in smaller vehicles. Additionally, not all tire shops are equipped to install or service run flat insert, which can limit availability in certain regions.

Nonetheless, these limitations are gradually being addressed through innovation, broader market adoption, and expanded training for technicians.

The Future of Run Flat Insert Technology

The evolution of run flat insert is just beginning. Researchers and manufacturers are developing lighter, more efficient designs using nanocomposite materials and smart polymers. Future inserts may also include sensors to detect pressure loss and automatically alert drivers or fleet managers.

Integration with intelligent vehicle systems could allow automatic speed adjustment or route changes in the event of a flat. As electric and autonomous vehicles become more mainstream, run flat insert will play a crucial role in ensuring uninterrupted mobility without human intervention.

Consumer-level applications are also expected to grow, especially as safety-conscious drivers seek more robust alternatives to spare tires.

Staying in Motion with Confidence

Run flat insert is more than a technological innovation—it’s a practical, powerful tool that keeps vehicles moving when it matters most. Whether navigating a battlefield, transporting goods, or simply avoiding a roadside emergency, this solution provides peace of mind and operational security.

By understanding its capabilities, applications, and future potential, users across industries can unlock new levels of performance and reliability. No pressure? No problem—thanks to run flat insert.