🔑 Key Benefits & Features

1. High Durability and Long-lasting Performance

Our plastic injection mold parts are built to withstand the toughest working conditions. The ABS, PP, and PC materials used are well-known for their exceptional impact resistance and dimensional stability, which means they can handle the pressure and strain of high-cycle, high-volume production without deteriorating. Whether in industrial manufacturing or consumer goods, these parts will maintain their integrity over time.

2. Food Safety and Hygiene Assurance

As our injection mold parts are made from food-grade plastics, they meet the highest standards for food safety. This ensures that they are not only safe for food contact but also resistant to the buildup of harmful bacteria and contamination. This makes them perfect for food processing, beverage containers, and kitchen appliances where hygiene is paramount.

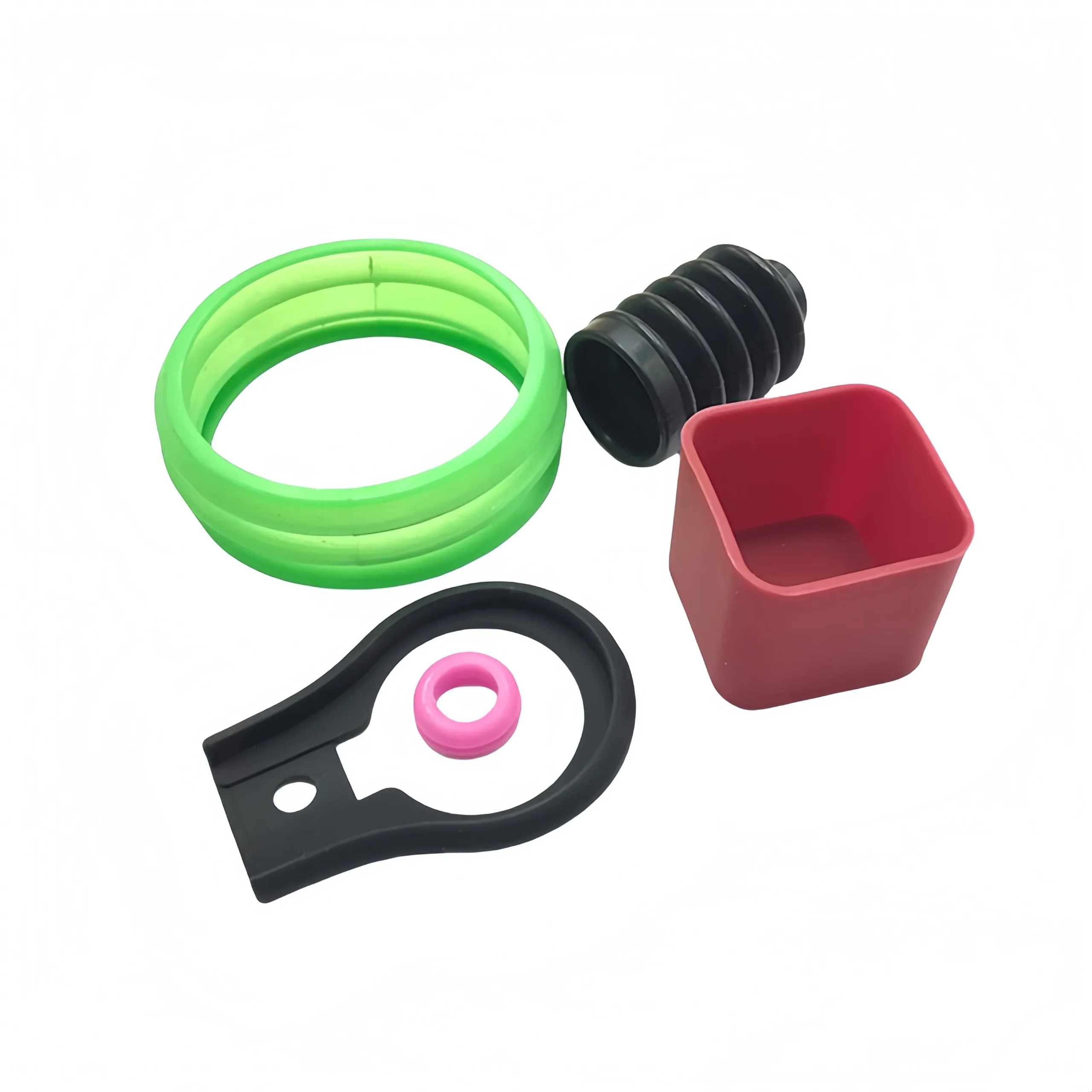

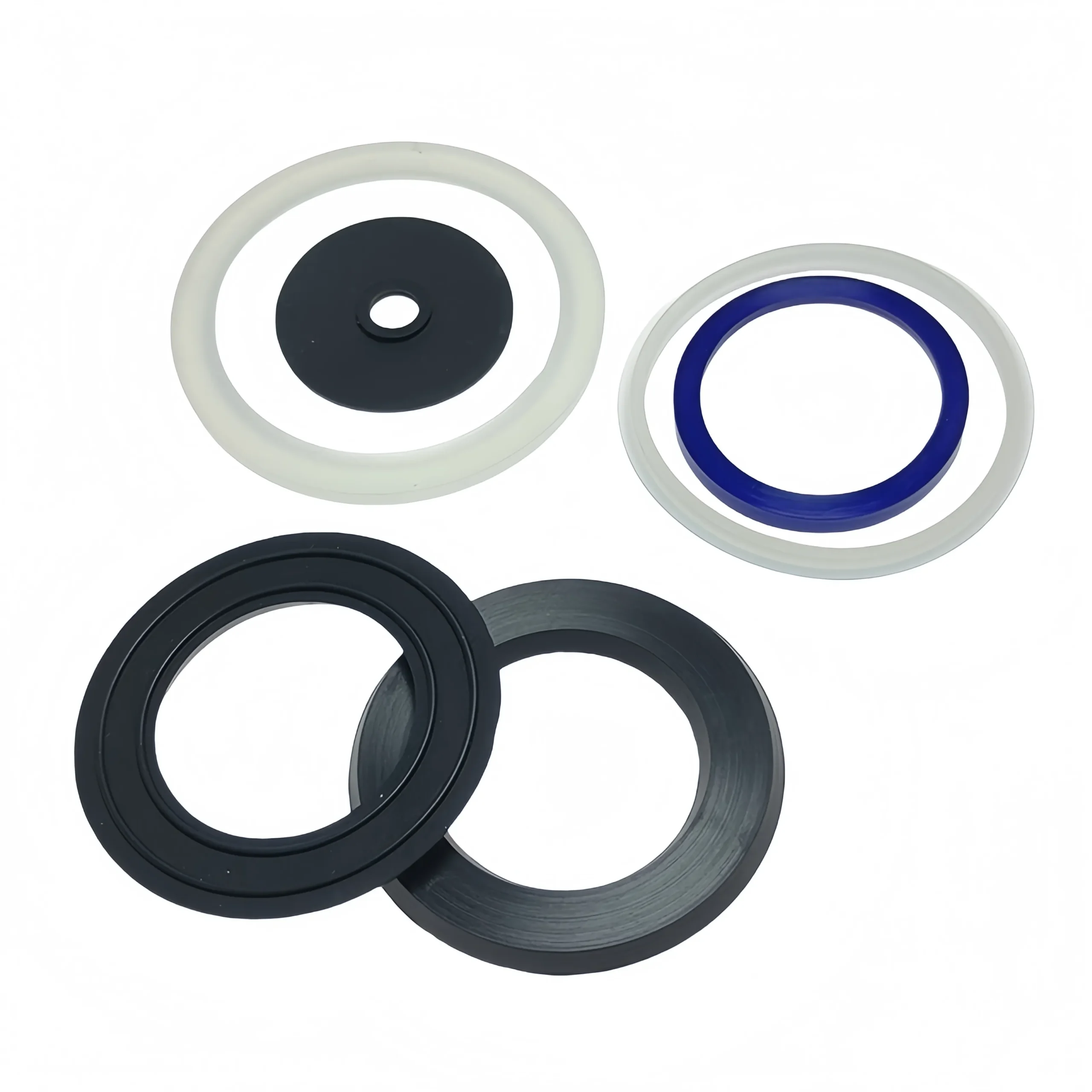

3. Custom Design Flexibility

Every project is unique, and our plastic injection molding capabilities provide the flexibility to produce parts in various sizes, shapes, and finishes. Whether you need small, intricate components or large, heavy-duty molds, our advanced machinery can cater to the most specific design requirements. Customization options include color matching, texture, and surface finishes such as matte or glossy effects.

4. Chemical & Heat Resistance

Especially suitable for automotive, medical, and electronic applications, the materials we use (ABS, PP, and PC) offer excellent resistance to chemicals, heat, and UV rays. This makes our injection molded parts ideal for products that are exposed to extreme conditions, including high temperatures, UV exposure, and harsh chemical environments. The PC material particularly excels in high-temperature applications, ensuring your parts won’t degrade or lose performance under heat stress.

🛠️ Common Applications & Industries

Our plastic injection mold parts are trusted across multiple industries for their reliability, safety, and long-term performance:

Food & Beverage Industry

-

Containers (bottles, jars, trays)

-

Packaging components (lids, caps, packaging materials)

-

Kitchen tools (cutlery handles, appliance parts)

-

Food-safe packaging (single-use or reusable packaging)

Medical & Pharmaceutical

-

Sterile medical device casings

-

Pharmaceutical containers and closures

-

Medical instrument housings

-

Labware and diagnostic kits

Consumer Electronics & Home Appliances

-

Smartphone cases

-

Appliance parts (microwave doors, blender components)

-

Control panels and enclosures

-

Cable connectors and plugs

Automotive Industry

-

Interior panels

-

Cable management parts

-

Exterior trim

-

Protective casings

Industrial & Heavy-Duty Manufacturing

-

Mechanical components

-

Gears and connectors

-

Machine enclosures

-

Filtration systems

With high versatility and easy integration into your manufacturing lines, these injection mold parts ensure top-notch performance and seamless production workflows.

🌍 Sustainability & Eco-Friendliness

We are committed to minimizing our environmental impact. Our plastic materials (ABS, PP, and PC) are recyclable, and we continually work toward reducing waste during the injection molding process. Additionally, we focus on energy-efficient production methods that reduce carbon emissions while maintaining the highest quality standards.

🌟 Why Choose Our Injection Mold Parts?

-

Exceptional Quality Control: Every part undergoes rigorous testing and inspection to ensure precision, durability, and compliance with food-grade standards.

-

Comprehensive Support: From initial inquiry to delivery, our team provides full customer support, including technical consultation, design assistance, and after-sales service.

-

Competitive Pricing: By leveraging our advanced manufacturing processes and efficient production systems, we offer high-quality parts at competitive prices, ensuring great value for your investment.

-

On-Time Delivery: With our efficient logistics network, we guarantee that your parts will arrive on schedule, no matter where you are located.

📦 Packaging & Delivery Process

To ensure the safe arrival of every batch, each set of plastic injection mold parts is:

-

Individually checked for defects or imperfections before packaging

-

Packed in shock-resistant, moisture-proof cartons to prevent damage during transit

-

For bulk orders, parts are carefully palletized and secured with stretch film to reduce movement during shipping

-

Clear labeling helps ensure efficient warehouse handling and easy identification upon receipt

-

Tracking information is provided for all shipments, so you can monitor the progress of your order in real-time

We offer international shipping and can fulfill orders from small batches to large-volume requests with quick turnaround times.

💡 Contact Us for Custom Orders or Further Information

If you have specific requirements or need custom injection mold parts for a particular project, our team is happy to assist with tailored solutions. Reach out to us for a quote, technical specifications, or to discuss your design needs.

Let our high-quality injection mold parts help you streamline your production process, improve your product quality, and ensure the long-term success of your business.

There are no reviews yet.