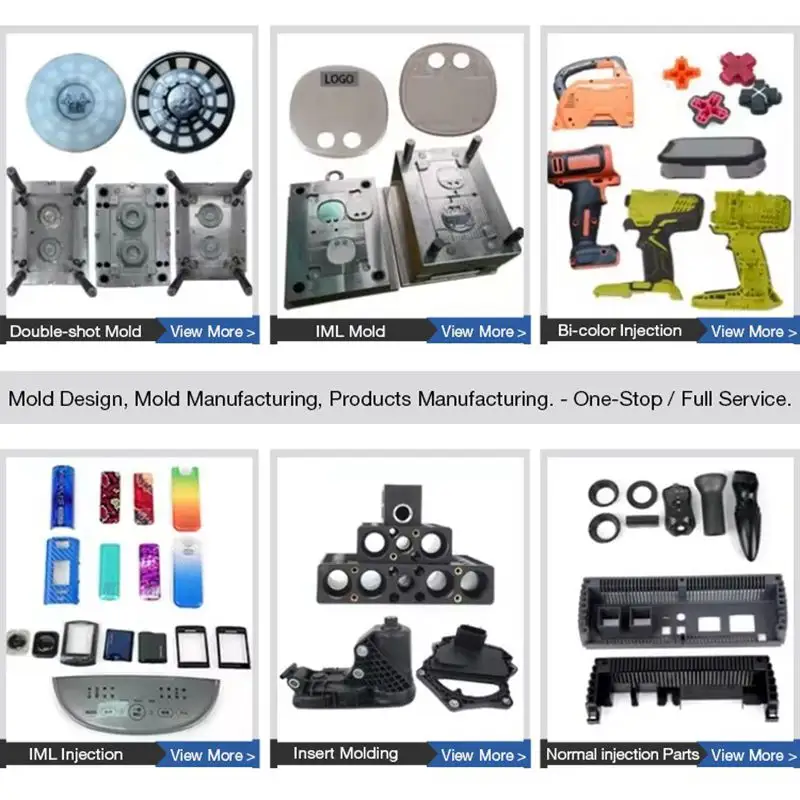

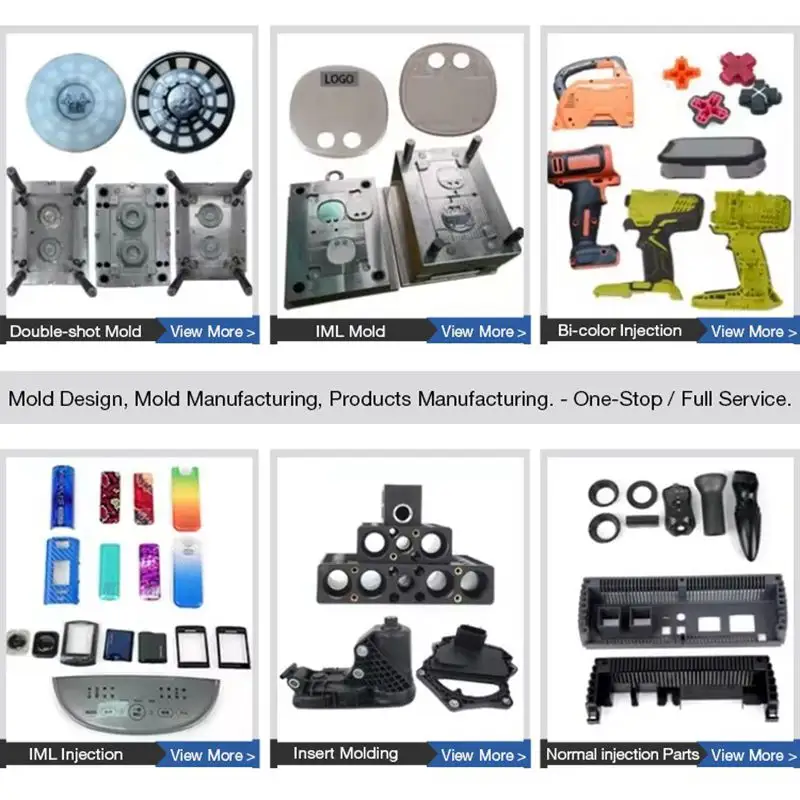

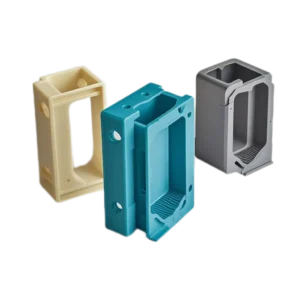

Our Injection Machine Parts are crafted for high-performance and exceptional reliability, making them the perfect solution for a wide range of manufacturing applications. Whether you’re working in automotive, electronics, medical devices, or consumer goods, these components will ensure that your injection molding processes operate seamlessly and efficiently. Designed for speed and optimized for longevity, these machine parts offer the perfect blend of precision, strength, and endurance to maximize production output and reduce operational downtime.

Usage Scenarios

Injection molding is a critical process in numerous industries, and the quality of your injection machine parts plays a pivotal role in the success of this process. These high-performance components are ideal for industries that require precision molding of plastic or metal parts, such as:

-

Automotive Manufacturing: For producing parts like bumpers, dashboards, and interior components, where high-volume and consistent quality are essential.

-

Consumer Electronics: Perfect for molding intricate components like casings, buttons, and connectors for devices that demand high precision and durability.

-

Packaging Industry: Ensuring reliable production of packaging materials like bottles, containers, and closures, optimizing the speed of production lines.

-

Medical Devices: Offering dependable performance when creating complex medical components where hygiene and reliability are paramount.

Whether used in small-scale operations or large-scale production environments, these injection machine parts are designed to enhance efficiency and maintain product quality, allowing you to meet industry demands.

Engineered for Speed and Precision

Every component is designed to help you achieve superior performance at higher speeds. These injection machine parts feature precision engineering that minimizes friction, ensuring smooth operation at all stages of the injection molding cycle. With an optimized design that accommodates the intricate details of injection molding processes, they help in reducing cycle times without compromising on the quality of the molded parts. The result is higher productivity with fewer disruptions, ensuring a more consistent output for your business.

The components are designed to meet the most demanding production environments, offering reduced wear and tear, which means fewer maintenance interruptions and extended machine lifespans. When you choose these parts, you’re investing in more than just a product; you’re investing in efficiency and reliability that keeps your operations running at peak performance.

Material Quality and Durability

Constructed from premium materials, these injection machine parts are built to endure the high pressures and temperatures involved in injection molding. We use only the best quality alloys and high-strength materials that resist corrosion, wear, and thermal degradation, making them durable even in the most demanding conditions.

The materials used are also engineered to minimize friction and heat buildup, both of which are common causes of part degradation in injection machines. By providing enhanced wear resistance and improved operational efficiency, these parts ensure that your machines continue to operate smoothly, even during long production runs.

The high-grade steel, precision castings, and durable surface coatings used in our injection machine parts guarantee that they can withstand the stresses of continuous operation, ensuring a long-lasting solution for your manufacturing needs.

Why Choose Our Injection Machine Parts?

-

Speed & Efficiency: Engineered to optimize the molding process, these parts reduce cycle time while maintaining precision and product quality.

-

Reliability & Durability: Built to withstand high pressure, temperatures, and constant wear, ensuring a longer lifespan for your machinery.

-

Precision Engineering: Our parts are designed with accuracy to reduce downtime and improve the overall performance of your injection molding machines.

-

High-Quality Materials: Made with high-strength alloys, corrosion-resistant finishes, and thermal-resistant coatings for maximum durability.

By upgrading to our injection machine parts, you’re investing in a solution that enhances your productivity, reduces downtime, and boosts the reliability of your injection molding machines, ultimately driving your bottom line forward.

There are no reviews yet.