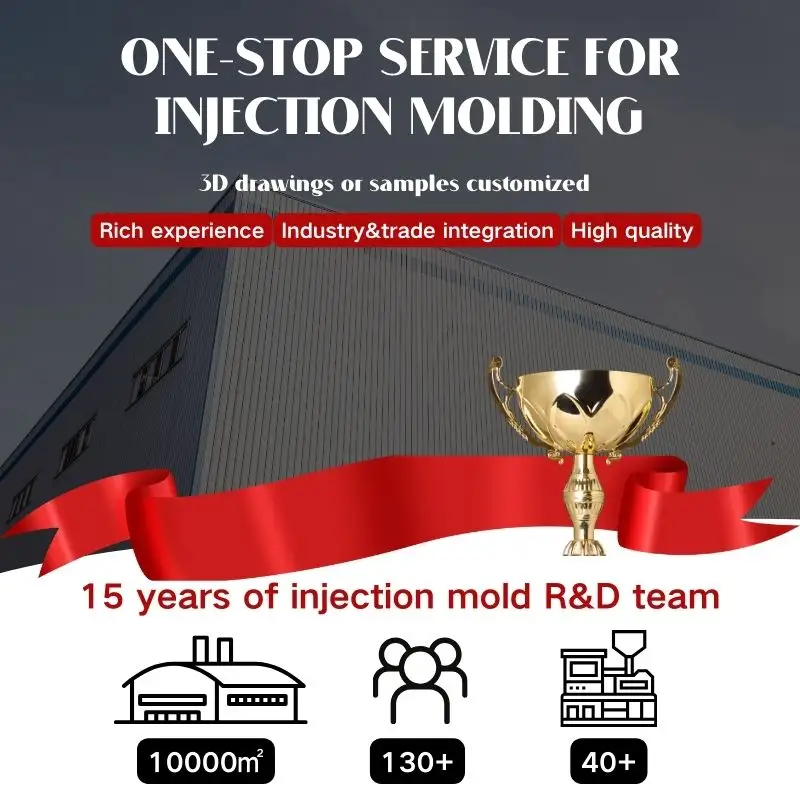

Our Plastic Injection Mould Manufacturer Service for Plastic Parts provides an all-encompassing solution for industries seeking high-precision, durable plastic components. Specializing in manufacturing injection machine parts, we offer a tailored, efficient, and reliable service to meet the exact specifications of your products, ensuring both optimal functionality and cost-effectiveness.

Injection Machine Parts Parameters

| Place of Origin | hebei, China |

| Brand Name | FeiNuo |

| Plastic Modling Type | Injection |

| Product name | plastic parts |

| Size | customized |

| Color | customized |

| OEM | support |

| Teeth Number | customized |

| Payment | according to cst needs |

| Shape | customized |

| Type | factory direct |

| Price | negotiable |

Usage Scenarios:

Our injection moulding services are essential for a wide range of industries that require custom, high-quality plastic parts. These include:

-

Automotive Industry: For parts like dashboards, handles, and interior components that require durability and precision.

-

Electronics Industry: Providing custom enclosures and components for devices like smartphones, tablets, and household appliances.

-

Industrial Machinery: Specializing in injection machine parts such as nozzles, gears, and other essential components that enhance machine performance.

-

Consumer Goods: From kitchen gadgets to household tools, we provide high-precision parts that meet the demands of modern consumer products.

Whether you’re creating components for heavy machinery or intricate parts for daily consumer products, our injection moulding service is designed to deliver exceptional performance.

Manufacturing Process:

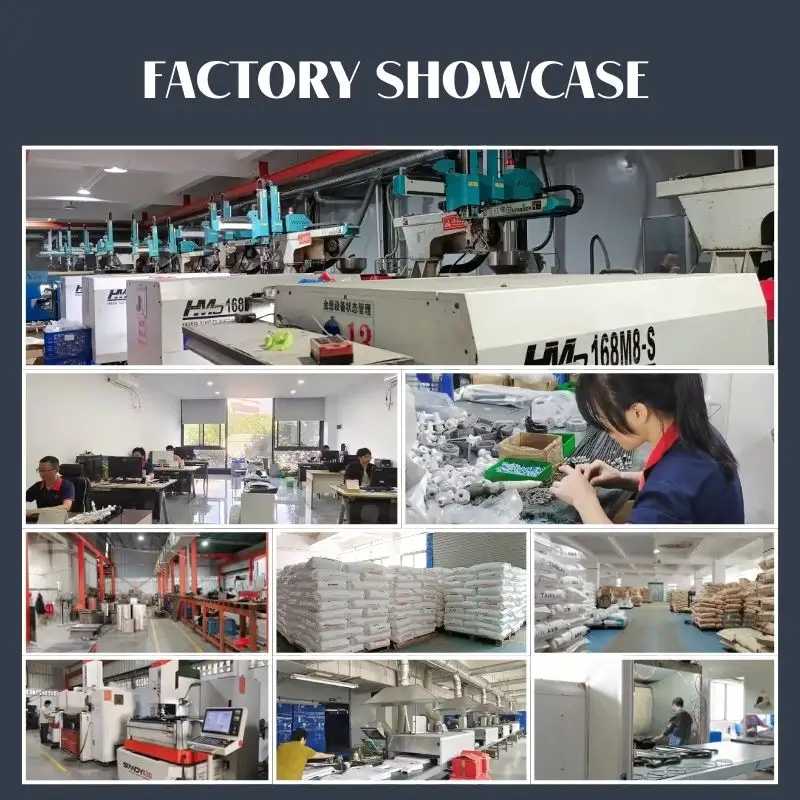

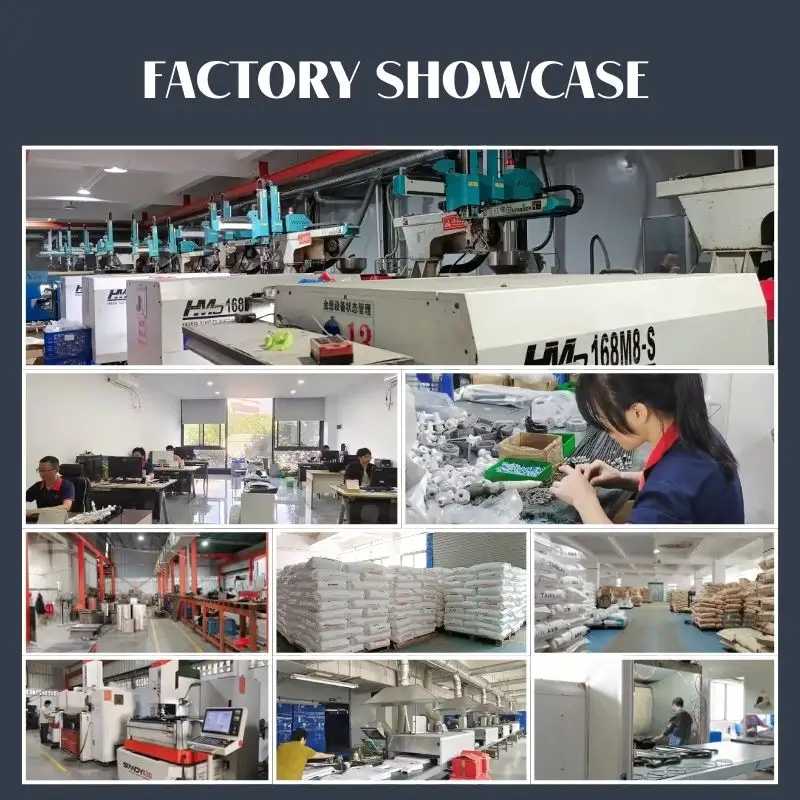

Our manufacturing process begins with understanding your specific needs. Our team of experienced engineers works closely with you to design the ideal injection mould that will create your parts with the utmost precision.

-

Design & Prototyping: We start by creating a digital 3D model of your plastic part. This design is then turned into a prototype for testing, allowing you to verify that the part fits your needs before we proceed with full production.

-

Tooling: Once the design is approved, we proceed to build the mould. This is done with state-of-the-art machinery and technology to ensure every detail is meticulously crafted.

-

Injection Moulding: Using advanced injection moulding machines, high-quality plastic is injected into the mould under controlled temperature and pressure. This ensures uniformity and precision in every part produced, particularly for injection machine parts that need to withstand high temperatures and pressure in their respective machinery.

-

Quality Control: Each product undergoes thorough quality inspection to guarantee that it meets strict industry standards. We check for consistency in dimensions, surface finish, and material strength to ensure durability and reliability.

Material Information:

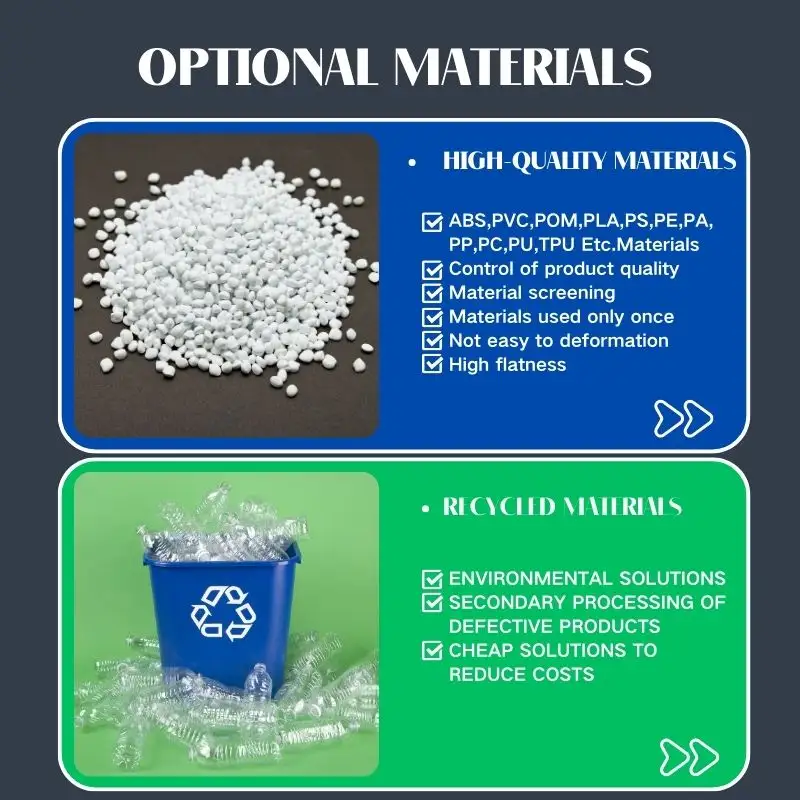

We use a wide range of high-quality plastics tailored to your needs. These include:

-

ABS (Acrylonitrile Butadiene Styrene): Known for its toughness and impact resistance, ABS is often used for durable consumer goods and automotive parts.

-

Polycarbonate: A strong, transparent plastic that offers excellent impact resistance, perfect for electronics and machine parts.

-

Polypropylene (PP): Known for its chemical resistance and low density, ideal for applications where weight reduction is important.

-

High-Density Polyethylene (HDPE): Known for its strength and resistance to chemicals and wear, making it ideal for industrial components, including injection machine parts.

These materials are chosen based on your product’s intended use, ensuring that every part is strong, reliable, and able to perform in the most demanding environments.

Packaging and Shipping:

Once the manufacturing process is completed, we focus on packaging and shipping to ensure your products reach you in perfect condition. We offer:

-

Customized Packaging: Each part is carefully cleaned, inspected, and individually packed with protective materials such as bubble wrap or foam to prevent damage during transit.

-

Efficient Shipping: Whether you’re located locally or internationally, our shipping options are fast and secure. We collaborate with trusted logistics partners to guarantee on-time delivery, no matter the destination.

We understand the importance of receiving your injection machine parts and other plastic components on time, so we prioritize swift processing and transparent communication throughout the entire shipping process.

Why Choose Us:

-

Precision & Customization: Our expert team delivers parts tailored to your exact specifications, ensuring optimal performance for your machines or products.

-

Advanced Technology: We use cutting-edge injection moulding technology to create high-precision parts with a quick turnaround.

-

Durable Materials: We carefully select the best materials for your project, ensuring the longevity and strength of every part.

-

Global Delivery: We offer worldwide shipping to ensure your products reach you, no matter where you are.

Choose our Plastic Injection Mould Manufacturer Service for Plastic Parts and experience the perfect balance of quality, precision, and reliability. Whether you’re looking for individual components or mass production of injection machine parts, our service will meet your needs with excellence.

There are no reviews yet.